In the fashion-manufacturing sector, quality is the key credibility asset. A single flawed shoe or handbag can undermine years of brand equity. At XINZIRAIN, we treat quality control not as a checkpoint but as a holistic, embedded discipline—deploying rigorous standards, advanced technologies and skilled craftsmanship to ensure every product meets global expectations for durability, comfort and finish.

This guide outlines common quality issues in footwear and handbag production and details how XINZIRAIN prevents them through systematic inspection, testing, and continuous improvement—with data-backed evidence to illustrate the stakes and benchmarks.

Common Quality Challenges in Footwear & Handbag Production (With Data)

Adhesive Overflow & Poor Finishing

When bonding components (e.g., soles, bag panels), too much glue can leave visible residue, degrade aesthetics and signal low craftsmanship.

Data point: A research project examining shoe production found that bonding defects (i.e., weak bonds, adhesive overflow) accounted for 21.6% of all defect types in one factory’s print-out of “critical to quality” issues.

XINZIRAIN solution: Operators are trained in calibrated adhesive application; high-grade eco adhesives with optimal viscosity are used; QC inspections utilise UV or residue detection to catch glue overspill early.

Weak Adhesion or Stitch Failure

Detachment of soles from uppers (shoes) or handles from bag bodies represent serious functionality/durability issues. Visual inspection alone often misses these until field returns.

Data point: Industry guidance suggests that in footwear, a baseline defect/reject level sits at around 2% of units produced, noting that “the figure is almost certainly an underestimate.”

XINZIRAIN solution: We maintain a material-glue match database, perform tensile and peel testing (e.g., in line with ISO 17708, ISO 24266), and reinforce stress-points with double stitching or additional bonding layers.

Surface Marks, Scuffs & Discoloration

Leather, patent, coated fabrics and vegan alternatives are prone to scratches, scuffs or colour inconsistency—impacting perceived quality, especially in premium segments.

Data point: A leather bag manufacturer case study found an average defect rate of around 14.94% (717 defective units out of 4,800 produced) across a 16-month period, with top defects being loose stitching, peeling leather and untidy glue application.

XINZIRAIN solution: Production uses soft contact surfaces, protective films, microfiber gloves for handling, pre-finishing inspections under colour-neutral lighting, and if needed, application of natural waxes/conditioners to restore finish.

Symmetry and Structural Inaccuracy

Out-of-shape silhouettes, mis-aligned seams or mismatched left/right assemblies degrade wearability and visual balance.

XINZIRAIN solution: We deploy digital pattern calibration systems, 3D scanning for wearlast fit, laser edge guides for bag assembly, and 3D measurement tools to verify left-right symmetry against a master sample.

Incorrect Sizing or Dimensional Deviation

Incorrect shoe sizes or bag dimensions can stem from worn-out tooling, inadequate calibration or packaging mis-handling. These errors contribute to returns and erode trust.

XINZIRAIN solution: Tools and jigs are subject to regular calibration. Fit-test protocols (including 3D moulds for shoes, dimension scanners for bags) are used per batch. Clients’ specification sheets are cross-checked before final pack-out.

Hardware & Metal Safety Issues

Bags often incorporate metal fittings; shoes may contain tacks or nails. Sharp edges, rust or loose hardware reduce safety and quality perception.

Data point: In the luxury handbag production context, one high-profile factory reportedly had a defect/waste rate of up to 40% of hides or units due to assembly/cutting errors.

XINZIRAIN solution: All hardware undergoes salt-spray corrosion testing, pull-strength cycling (5,000+ cycles); metal detectors ensure no stray needles/tacks remain in shoes; fitting edges are polished and inspected.

Sole or Handle Separation

Bonding failures under flex or wear conditions lead to sole separation (shoes) or handle detachment (bags) — a major durability and warranty risk.

XINZIRAIN solution: Automated pressing/curing machines with temperature and pressure sensors ensure consistent bonding; random sample flex-and-fatigue tests are performed to validate assembly integrity.

Testing Procedures at XINZIRAIN Laboratories

| Test Name | Purpose | Implementation at XINZIRAIN |

|---|---|---|

| Bond Strength | Verifies adhesion between components | Tensile and peel testing aligned with ISO 17708:2018/ISO 24266 standards |

| Colorfastness | Ensures stable dye and surface colour behaviour | Wet & dry rubbing tests; leather/fabric resistance verification |

| Abrasion Resistance | Measures wear-out behaviour | Martindale or similar abrasion testers |

| Slip & Traction | Confirms outsole grip across surfaces | Simulated coefficient of friction tests on wet/dry floors |

| Waterproofing | Checks water penetration resistance | Immersion or spray chamber tests for shoes/bags |

| Chemical Compliance | Ensures materials meet REACH/CPSIA/regulatory limits | Full lab chemical composition analyses |

| Hardware Strength & Cycling | Validates bag fittings / shoe metal parts | Pull-and-cycle tests (e.g., 5,000 opening/closing operations) |

| Fit & Comfort | Ensures ergonomic and structural standards | Fit testing, ergonomic wear simulation, foot mould measurement (for shoes) |

XINZIRAIN’s Integrated Quality Control Framework

Defined Global Quality Standards

We document precise standards for materials, manufacturing, finish, safety and packaging—mapping to EU and US import regulations, along with brand-specific criteria. All specs are maintained in our Quality Manual.

Supplier Certification & Audit

Our supplier partners must hold certifications such as Leather Working Group (LWG) Gold, OEKO-TEX®, ISO 9001, etc. Annual audits and supplier scorecards monitor material quality, traceability and sustainability performance.

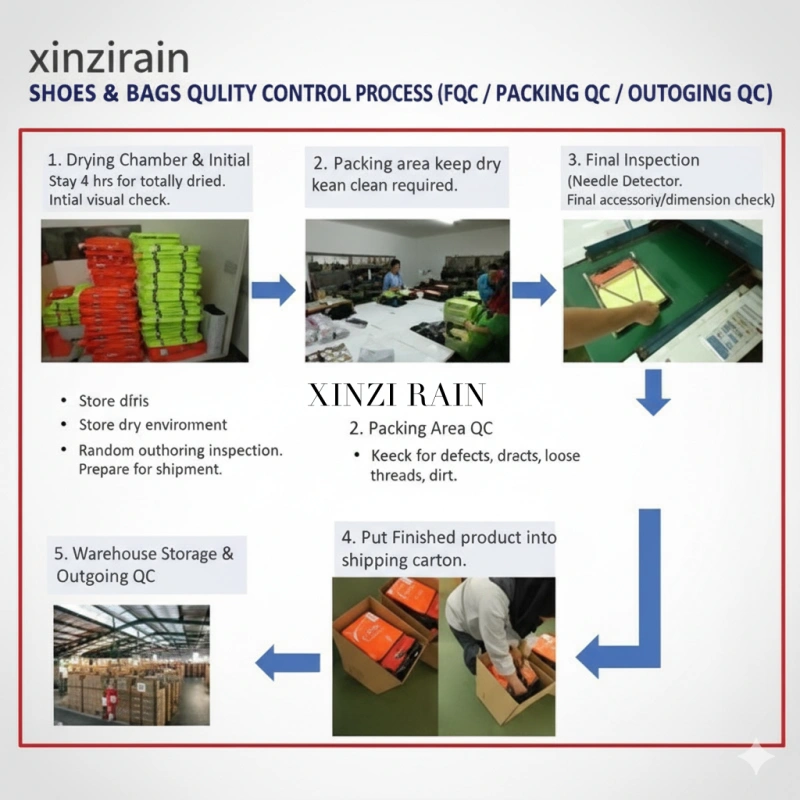

Multi-Stage Quality Checks

We implement a three-tier inspection system:

-

Incoming Materials Inspection – leathers, textiles, adhesives, hardware

-

In-Process Inspection – after stitching/assembly, mid-line checks

-

Final Pre-Shipment Inspection – applying AQL (Acceptable Quality Limit) standard of 2.5/4.0 or stricter depending on client.

Real-Time Data & Monitoring

Advanced dashboards aggregate QC data in real time: defect occurrences, trend analysis, root-cause alerts. Automated adhesive dispensers and camera-based inspection tools reduce human error.

Documentation & Traceability

Each production lot bears a unique batch code linking to raw material lots, operator IDs, machine IDs, inspection check-sheets and lab test results. This enables rapid trace-back in the event of any deviation.

Beyond Inspection: Craftsmanship, Sustainability & Continuous Improvement

Skilled Craftsmanship Meets Automation

Our manufacturing teams average 10-15 years’ experience. While CNC cutters and CAM systems handle high-precision tasks, human artisans focus on finish, edge-trim, hand-stitch and quality verification, ensuring both scale and sophistication.

Sustainable & Responsible Production

We embed a “zero-defect, low-waste” ethos. Off-cut materials are recycled, water-based adhesives are standard, and we implement process improvements aligned with sustainability standards. (See broader industry note on sustainable manufacturing strategies.)

Training & Continuous Improvement

Workers participate annually in quality-awareness training; QC inspectors receive ISO-aligned certification. Monthly internal audits and client feedback feed into our CAPA (Corrective & Preventive Action) system for ongoing upgrades.

Why Brands Choose XINZIRAIN

-

Comprehensive QC & test-report documentation, ready for importers/distributors

-

Proven track record of meeting ISO, REACH, CPSIA and other global standards

-

Flexibility for small MOQs without compromising on production quality or inspection rigour

-

Integrated design-to-factory support for private-label brands targeting EU & Americas

-

Data-driven quality assurance: e.g., aiming for defect levels well below industry baseline (~2% for footwear)

Final Thoughts

At XINZIRAIN, quality control isn't just a step—it’s a culture threaded through every phase of design, sourcing, production and shipment. Backed by industry-benchmark data, advanced testing and craftsmanship, we guarantee footwear and handbags that not only look premium but also perform reliably.

Your brand deserves products that reflect your vision and your promise—one flawlessly crafted piece at a time.

Stay Connected with XINZIRAIN

Stay inspired with the latest footwear trends, design insights, and manufacturing updates from XINZIRAIN — your trusted OEM/ODM shoe & bag manufacturer in China.

Follow us on social media for exclusive product previews, behind-the-scenes craftsmanship, and global fashion insights:

Join the XINZIRAIN community — where quality, creativity, and craftsmanship meet global fashion.