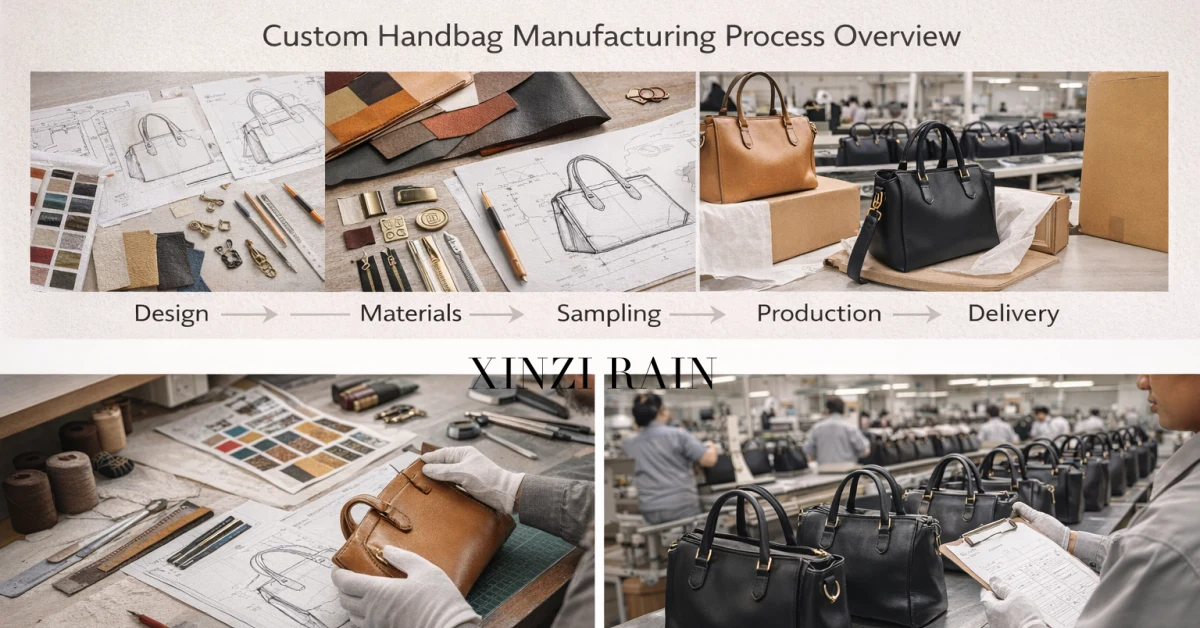

Understanding the custom handbag manufacturing process empowers brands to make better design, pricing, and production decisions. This guide outlines how professional handbag factories transform concepts into scalable, market-ready products.

The process described below reflects real OEM workflows used by experienced manufacturers such as XINZIRAIN, serving international brands.

Step 1: Design Concept & Technical Translation

Manufacturing begins with interpretation, not production.

Design inputs may include:

-

Hand sketches or reference products

-

Functional requirements

-

Target price positioning

These inputs are translated into technical drawings, measurements, and construction logic to ensure the design is manufacturable at scale.

Step 2: Material & Hardware Engineering

Material selection affects performance, cost, and brand perception.

Professional handbag manufacturers evaluate:

-

Leather thickness and grain stability

-

Vegan and recycled alternatives

-

Hardware load-bearing strength

-

Colorfastness and aging behavior

XINZIRAIN’s material selection process balances aesthetic intent with durability and market compliance.

Step 3: Sample Development & Iteration

Sampling is a controlled testing phase.

Brands typically refine:

-

Structure and proportions

-

Stitching density and reinforcement

-

Closure systems and hardware placement

-

Logo visibility and branding balance

Multiple sample iterations are standard for serious private label development, ensuring the final product performs as intended.

Step 4: Cost Confirmation & Production Planning

Once samples are approved, manufacturers finalize:

-

Unit cost structure

-

Production lead times

-

Packaging specifications

Transparent cost breakdowns help brands plan pricing and margins accurately.

Step 5: Bulk Production & Quality Control

During mass production, quality is managed through:

-

Material batch inspections

-

In-line assembly checks

-

Final product audits

Experienced OEM bag factories focus on consistency across every unit—not just the first sample.

Step 6: Packaging, Logistics & Global Delivery

Final steps include:

-

Custom packaging solutions

-

Export-compliant labeling

-

Coordination with international logistics partners

Manufacturers supporting global brands often assist with shipping documentation and delivery planning.

Why Process Transparency Matters

Brands that understand the custom handbag manufacturing process:

-

Communicate more effectively with factories

-

Reduce development risks

-

Improve speed-to-market

-

Build stronger long-term partnerships

This transparency is essential for sustainable brand growth.

FAQ

1: What are the main stages of the custom handbag manufacturing process?

The process includes design development, material and hardware selection, sample production, cost confirmation, mass production, quality control, and global delivery.

2: How long does custom handbag manufacturing usually take?

Timelines depend on design complexity and order volume. Sampling typically takes several weeks, while bulk production follows after approval. Experienced OEM manufacturers provide clear timelines at each stage.

3: What happens if changes are needed after the first sample?

Revisions are a standard part of OEM development. Professional manufacturers allow multiple sample iterations to adjust structure, materials, hardware, and branding until the product meets expectations.

4: How do manufacturers ensure consistent quality in bulk production?

Quality is controlled through material inspections, in-line production checks, and final product audits. Established OEM factories implement standardized QC systems to maintain consistency across all units.

5: Can manufacturers support sustainable handbag production?

Yes. Many manufacturers, including XINZIRAIN, offer eco-friendly materials such as recycled leather, plant-based alternatives, and certified textiles, while optimizing production processes to reduce waste.

6: Why should brands understand the handbag manufacturing process?

Understanding the process helps brands communicate more effectively with factories, control costs, reduce development risks, and improve speed-to-market for private label handbag collections.