A Founder’s Perspective on Building Brands That Last

In footwear manufacturing, long-term thinking is not a mindset or a marketing philosophy. It is a practical advantage built into how successful brands and manufacturers operate.

After years of working with private-label brands, designers, and growing footwear companies, one reality becomes clear: brands that approach footwear manufacturing with a long-term strategy consistently perform better than those chasing quick wins.

Footwear manufacturing is not fast fashion. Shoes are engineered products. They require structure, accumulated know-how, and disciplined decision-making. This is why long-term thinking is not optional in footwear manufacturing — it is essential.

Footwear Manufacturing Is a System That Improves Over Time

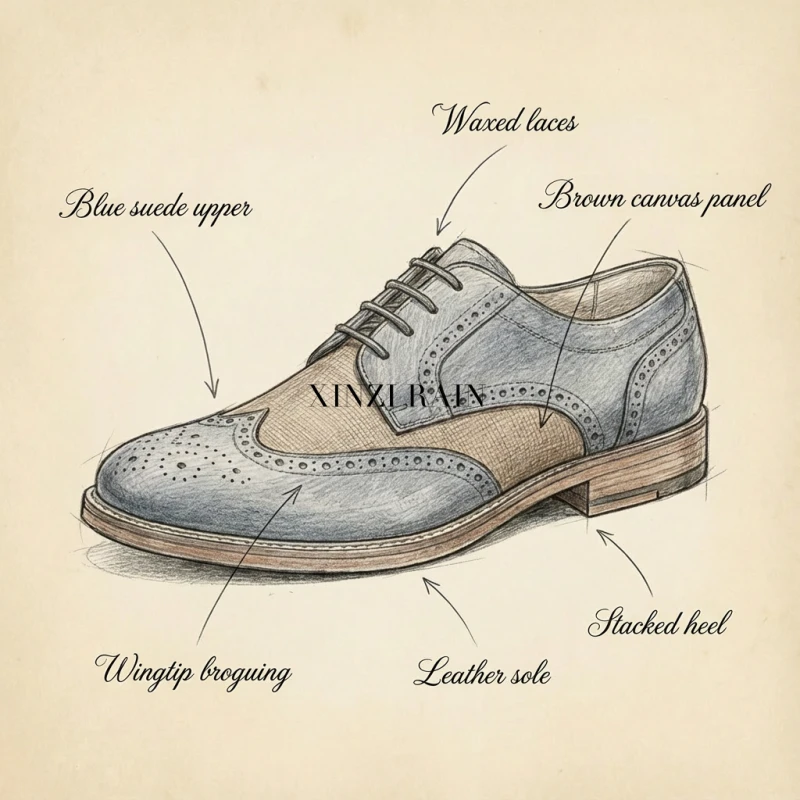

Footwear manufacturing does not start from zero every season. Each shoe design depends on interconnected systems, including last development, upper construction, sole structure, stitching methods, and material behavior.

When these systems are reused, refined, and improved over time, they deliver real advantages. Brands achieve better fit consistency, shorter development cycles, and fewer quality issues during bulk production.

Short-term thinking treats every collection as a new experiment. Long-term thinking treats footwear manufacturing as a system that becomes more reliable and efficient with every season.

This is why experienced footwear manufacturers prioritize continuity over constant reinvention.

Quality in Footwear Manufacturing Is Built, Not Purchased

In footwear manufacturing, quality cannot be created overnight. It is not the result of machines alone, but of skilled technicians, stable production teams, and clearly defined processes.

In practice, it takes several years for footwear technicians to develop the consistency required for premium production. Factories focused on short-term cost reduction often cut training investment or rely on frequent labor changes, which directly affects product consistency and defect rates.

The impact of these decisions is rarely immediate. Instead, problems appear later through returns, complaints, and damage to brand reputation. Long-term footwear manufacturing focuses on building capability first, preventing issues before they reach the market.

Sampling Is Where Long-Term Brands Reduce Risk

From a founder’s perspective, sampling is not just a development step. It is where most future production risks are either resolved or ignored.

In footwear manufacturing, proper sampling validates structure, material performance, comfort, and durability. Brands that rush sampling often face repeated revisions during bulk production, unexpected cost increases, and delayed launches.

By contrast, brands that invest in structured sampling cycles move into bulk production with greater confidence. Long-term thinking treats footwear sampling as risk management, not an expense to minimize.

Tooling and Materials Reward Consistency

Footwear manufacturing relies on long-term assets such as sole molds, hardware tooling, and stable material supply chains. These assets deliver value only when designs evolve rather than reset every season.

Brands that refine core silhouettes instead of constantly changing structures improve comfort, durability, and cost efficiency over time. This continuity allows footwear manufacturers to maintain consistent quality while reducing complexity.

Short-term design decisions often increase production risk. Long-term strategies simplify manufacturing while strengthening brand identity.

Real Cost Control Comes From Stability, Not Speed

In footwear manufacturing, true cost control does not come from faster timelines or lower unit prices. It comes from reducing errors, stabilizing specifications, and improving workflow predictability.

A single major bulk production mistake can eliminate the profit from several orders. Long-term manufacturing strategies focus on preventing mistakes rather than correcting them, which ultimately lowers total cost and protects margins.

This is why experienced footwear manufacturers may appear cautious. That caution is not inefficiency — it is informed risk management.

Trust Determines Scale in Footwear Manufacturing

Footwear manufacturing partnerships are rarely transactional. Brands depend on manufacturers to identify potential risks, protect intellectual property, and maintain consistency across collections.

These responsibilities require trust, which develops over time. Short-term suppliers often agree to every request without challenge, allowing issues to surface later. Long-term footwear manufacturers provide honest feedback early, even when it means slowing decisions in the short term.

From a founder’s point of view, this transparency is essential for sustainable brand growth.

Markets Reward Consistency Over Speed

While consumers may follow trends, the footwear market rewards reliability. Fit consistency, product durability, and dependable delivery schedules directly influence repeat purchases and long-term retail relationships.

Brands built on long-term footwear manufacturing strategies scale more smoothly, maintain pricing power, and navigate market changes with greater stability. Rapid growth without a manufacturing foundation often leads to operational strain rather than lasting success.

Conclusion: Long-Term Thinking in Footwear Manufacturing — The XINZIRAIN Approach

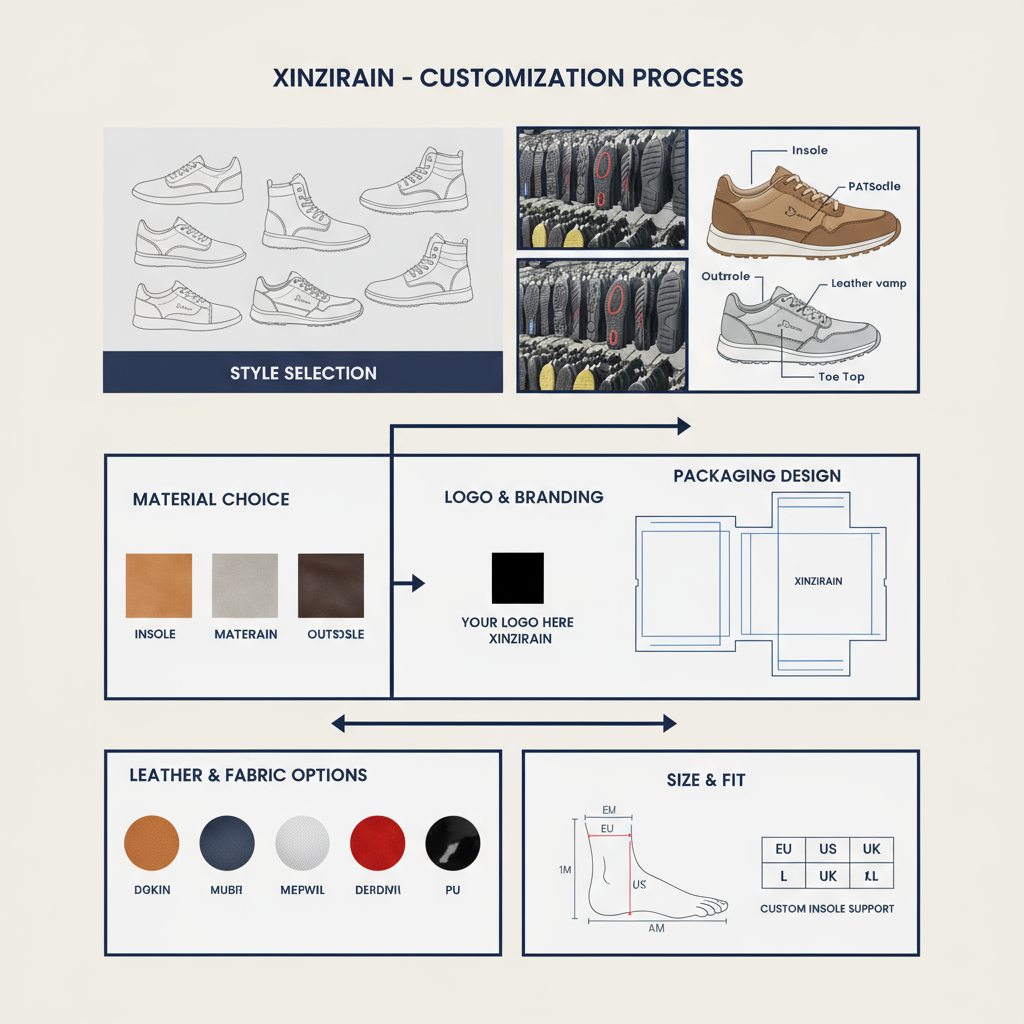

At XINZIRAIN, long-term thinking shapes how we work with brands at every stage.

We believe footwear manufacturing should support the entire brand journey, not just production. Successful brands are built through alignment — from early market research and positioning to design development, sampling, bulk production, and product launch support.

XINZIRAIN provides end-to-end support for private-label footwear brands, helping them reduce uncertainty, make informed decisions, and bring products to market with confidence. By identifying risks early and building scalable systems, we support sustainable brand growth rather than short-term output.

In footwear manufacturing, success is shared. If a brand struggles after launch, the manufacturer ultimately fails as well. This is why we operate on a simple principle: when our clients succeed, we succeed.

Long-term thinking allows us to protect brand value, reduce risk, and build partnerships that last beyond a single season. In footwear manufacturing, longevity is not accidental — it is the result of disciplined planning, experience, and shared responsibility.