Why material selection determines lifecycle cost

Leather choice governs mechanical performance (tensile, tear, abrasion), aesthetics (grain, gloss, colorfastness), process flow (edge finishing, adhesives, curing), and unit economics (yield, reject rate). The optimal specification balances brand positioning with use environment and testable quality metrics. XINZIRAIN converts those inputs into factory-ready specs: material → finish → construction → QC plan.

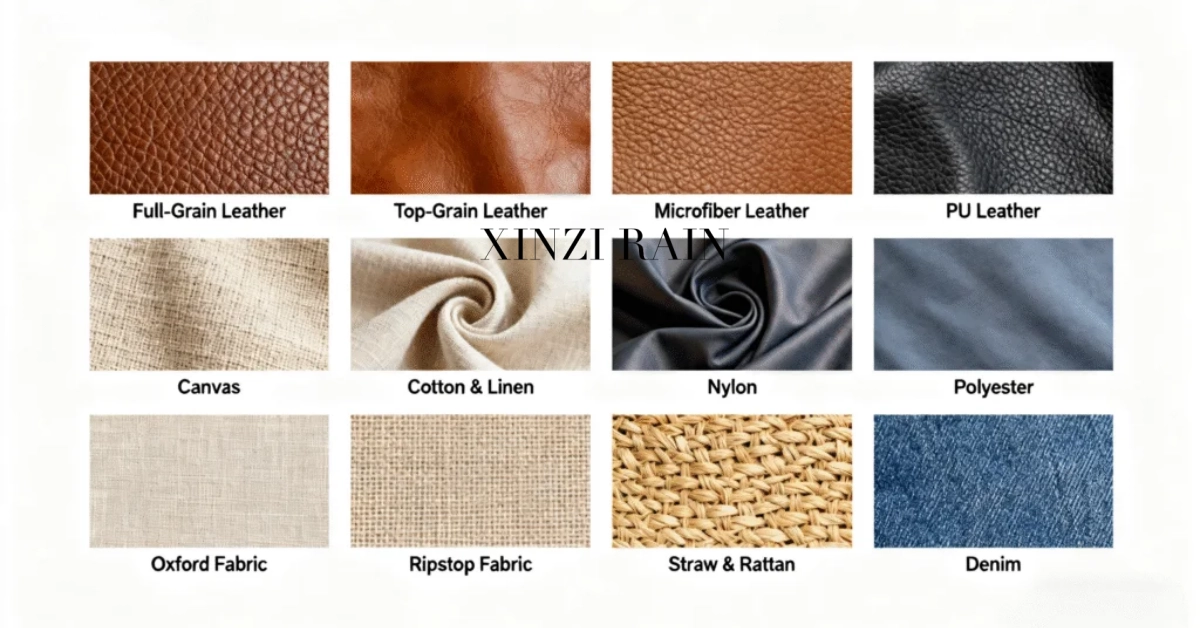

Leather categories and their engineering implications

| Category | Structure | Performance profile | Best use cases |

|---|---|---|---|

| Full-grain | Top hide with intact grain | Highest tear/abrasion, develops patina, breathable | Luxury totes, travel, heirloom lines |

| Top-grain | Lightly corrected upper layer | High strength, uniform surface, easier care | Premium daily/office bags |

| Corrected grain / Split | Sanded + pigmented lower layers | Cost-efficient, color stable | Trend/color-driven lines, entry price |

| Nubuck | Sanded full-grain face | Soft hand, premium look; sensitive to stains | Fashion pieces with care notes |

| Suede | Split with nap | Flexible, lightweight; lower abrasion | Seasonal, protected use |

| Engineered (Microfiber/PU) | Non-woven or coated textile | Low mass, wide color range; stable supply | Vegan/price-sensitive programs |

Specification note: Define thickness (mm), substance tolerance, and selection grade to stabilize yield and edge-paint behavior during mass production.

Coloration & finishes: performance vs. appearance

-

Aniline dyeing — minimal coating, visible natural grain.

Pros: highest breathability and hand. Trade-off: lower stain/UV resistance. -

Semi-aniline — thin protective topcoat over aniline.

Balanced choice for premium daily bags. -

Pigmented (protected) finish — polymeric surface film with pigments.

Pros: uniform color, scratch/stain resistance, UV stability. Ideal for light colors and humid markets. -

Special effects: Emboss (saffiano/croc), oil-pull-up, metallic/foil, pearlized.

Action: pair effects with rub-fastness and abrasion targets early in sampling to avoid down-stream rejects.

Tanning routes and compliance

-

Chrome (Cr III) tanning — soft hand, strong color, efficient cycle.

-

Vegetable tanning — plant tannins; firm body; beautiful aging; slower cycle.

-

Metal-free (wet-white) — lower residual metals; useful for stricter chemical policies.

Compliance to include in PO:

-

LWG-audited tannery, chromium VI non-detect, azo dye restrictions, REACH alignment for SVHCs, heavy-metal limits for hardware plating.

-

Water-based edge paints/adhesives where feasible.

Construction choices that change durability

Edges

-

Turned edge (wrapped): protects cut edge; softer feel.

-

Edge-paint system: multi-coat + sanding + curing; defines perceived quality—spec coat count and cold-crack target.

Seams & reinforcement

-

SPI (stitches per inch): set per seam load; higher SPI for visual finesse, lower for heavy seams.

-

Bar-tacks at handle roots; backer tape on stress seams; base boards/feet for shape retention.

Lining & interlayers

-

Cotton twill/microfiber/rPET; PU backers add memory to thin leathers; choose low-fogging materials for closed compartments.

Hardware

-

Alloy vs. brass; plating color; salt-spray resistance; spring tension for clasps.

-

Zip grade/chain size matched to mass (e.g., #8–#10 for travel).

Laboratory & in-process testing (spec examples)

Define tests up front and link them to acceptance criteria:

-

Color fastness to rubbing (dry/wet) — light/dark handled separately.

-

Abrasion — Martindale/Taber cycles for body, base, and straps.

-

Tensile & seam strength — strap attachment pull, stitch tear.

-

Edge-paint adhesion — cross-cut/tape, plus cold-crack for winter markets.

-

Hardware corrosion — neutral salt spray by hours vs. market climate.

-

Dimensional stability — heat/humidity cycling to validate packing/shipping.

XINZIRAIN runs 5-gate QC: incoming material → in-line → pre-closing → 100% function checks → AQL final.

Sustainability & traceability (pragmatic pathways)

-

LWG leather, water-based chemistries, solvent reduction plans.

-

Recycled inputs: rPET linings, recycled boards/foams, FSC packaging.

-

Plant-based options (on request): pineapple/cactus—set realistic abrasion and rub-fastness targets aligned to the use case.

Cost/MOQ engineering (keep quality, control BOM)

-

Cost drivers: grade, thickness, finish, cut yield.

-

Smart mixes: full-grain trims + protected body, or leather handles + microfiber panels to preserve touchpoints while stabilizing cost.

-

XINZIRAIN offers low MOQ pilots → scalable production once sell-through is proven.

XINZIRAIN’s development path (predictable timelines)

-

Brief & MSRP target → material/finish matrix with risks & alternates

-

Swatch deck + costed BOM and lead-time window

-

Proto 1 → fit/weight/edge-paint trials → feedback

-

Sales sample (color-accurate) → optional lab tests

-

PP sample (signed) → production → AQL final → export pack

Most programs reach retail-ready status in 2–3 iterations.

Decision presets (quick matches by scenario)

-

Luxury daily tote/backpack: full-grain or semi-aniline top-grain; turned edges; brass hardware; leather or twill lining.

-

Humid/rainy markets office bag: pigmented top-grain/corrected; rPET lining; robust edge paint; corrosion-resistant plating.

-

Color-led fashion crossbody: microfiber/PU for high color accuracy & low MOQ; foil/emboss options with defined rub targets.

-

Travel weekender: pebbled top-grain or protected split; reinforced base; #10 zipper; bar-tacks on stress points.

Why bleather bag OEMrands choose XINZIRAIN

-

25+ years in export manufacturing (bags & footwear)

-

OEM/ODM from design and materials to mass production

-

Low MOQ pilots; controlled scale-up

-

Compliance-ready supply chain and sustainability options

-

Europe/Americas logistics with retail-ready QC

Design your own bag with measurable quality: we define materials, finishes, and testing so your line performs on shelf and in use.

Stay Connected with XINZIRAIN

Stay inspired with the latest footwear trends, design insights, and manufacturing updates from XINZIRAIN — your trusted OEM/ODM shoe & bag manufacturer in China.

Follow us on social media for exclusive product previews, behind-the-scenes craftsmanship, and global fashion insights:

Join the XINZIRAIN community — where quality, creativity, and craftsmanship meet global fashion.