In handbag manufacturing, hardware plays a far greater role than simple decoration. Buckles, clasps, zippers, metal logos, D-rings, and chains determine how durable a bag is, how premium it feels, and how well it represents a brand’s identity. For OEM/ODM manufacturers and private-label brands, choosing the right hardware directly impacts cost, quality, and customer satisfaction.

At XINZIRAIN, we help global brands—from luxury labels to emerging designers—select the correct hardware materials and finishes while optimizing cost and production efficiency. This guide covers everything you need to know about bag hardware materials, their differences, and realistic factory pricing.

Why Hardware Quality Matters

Although hardware usually accounts for only 5–12% of a bag’s production cost, it significantly influences user experience and brand perception. Poor hardware can lead to peeling finishes, rust, scratches, broken buckles, mismatched colors, and high return rates—problems that directly affect brand reputation. For premium handbags, hardware is an essential touchpoint; its weight, sound, and finish create the luxury feel customers expect.

Choosing the right metal ensures long-term durability, fewer QC issues, and stronger product consistency across collections.

Common Hardware Materials Used in Bag Manufacturing

Different hardware materials offer different strengths, costs, and visual effects. Understanding these differences is essential before designing a collection.

Zinc Alloy — The Most Versatile and Cost-Effective

Zinc alloy is widely used in fashion and mid-range handbags because it can be molded into complex shapes and takes plating well. It offers smooth surfaces and good-looking finishes at a low cost. However, it is softer than stainless steel and not as premium as brass. Zinc alloy is ideal for decorative hardware, logo plates, and fashion-forward designs.

Brass — The Premium Choice for Luxury Brands

Brass hardware has a natural shine, excellent weight, and long-term corrosion resistance. It feels premium and ages beautifully, developing a slight patina over time. It is commonly used in luxury leather handbags, high-end logo plates, and signature buckles. Brass is more expensive and heavier, but unmatched in luxury appeal.

Stainless Steel — Durable and Rust-Proof

Stainless steel is incredibly durable, scratch-resistant, and anti-rust, making it suitable for bags designed for heavy use or outdoor wear. It is perfect for zippers, strap rings, and structural components requiring strength. However, stainless steel is harder to mold into intricate shapes and costs more than zinc alloy.

Aluminum — Lightweight and Modern

Aluminum is light, corrosion-resistant, and suitable for minimalist or travel bags where weight reduction is important. While clean and modern-looking, aluminum is easier to dent and not suitable for high-stress hardware components.

Choosing Hardware Finishes for Bag Design

The hardware finish affects both durability and aesthetic appeal. Popular finishes include polished gold, polished silver, matte nickel, antique brass, gunmetal, champagne gold, rose gold, and premium PVD plating. Each finish matches different bag styles:

-

Luxury handbags: polished gold, PVD, brass

-

Minimalist modern styles: matte nickel, gunmetal, stainless steel

-

Outdoor/travel bags: brushed stainless steel

-

Vintage bags: antique brass

-

Fast fashion: zinc alloy in bright plated tones

A well-chosen hardware finish enhances design coherence and elevates product quality.

Hardware Cost Comparison for OEM/ODM Manufacturing

Below is a practical cost reference based on common materials. Prices vary depending on size, thickness, finish, and complexity.

Hardware Material Cost Table

| Material | Typical Cost per Piece | Cost Level | Notes |

|---|---|---|---|

| Zinc Alloy | $0.05 – $0.30 | Low | Most common, excellent for fashion and decorative hardware |

| Aluminum | $0.08 – $0.40 | Moderate | Lightweight, modern look |

| Stainless Steel | $0.15 – $0.60 | Moderate–High | Extremely durable and rust-proof |

| Brass | $0.30 – $1.50 | High | Premium density and shine suitable for luxury bags |

Custom Mold Costs

-

Zinc alloy mold: $80 – $250

-

Brass mold: $150 – $400

-

Stainless steel mold: $150 – $350

Mold cost depends on engraving depth, complexity, and whether the hardware is 2D or 3D.

What Influences Hardware Pricing?

Several key factors affect final hardware cost:

-

Material density and weight — heavier metals like brass cost more to produce and plate.

-

Plating technology — water plating is cheaper; PVD plating offers superior durability at a premium price.

-

Mold complexity — intricate logos or unique shapes require higher mold costs.

-

MOQ and batch size — large batches significantly reduce unit price.

-

Polishing methods — manual polishing for luxury items increases labor cost.

-

Finish consistency requirements — matching hardware across multiple bag styles adds QC complexity.

Why Custom Hardware Matters for Branding

For brands seeking differentiation, custom hardware is a strong branding asset. Signature metal plates, engraved logos, and custom buckles help establish identity and increase perceived value. Custom hardware also improves anti-counterfeiting, enhances collection consistency, and makes the product instantly recognizable.

Popular custom hardware types include logo plates, specialty buckles, zipper pullers, chain designs, and decorative metal elements.

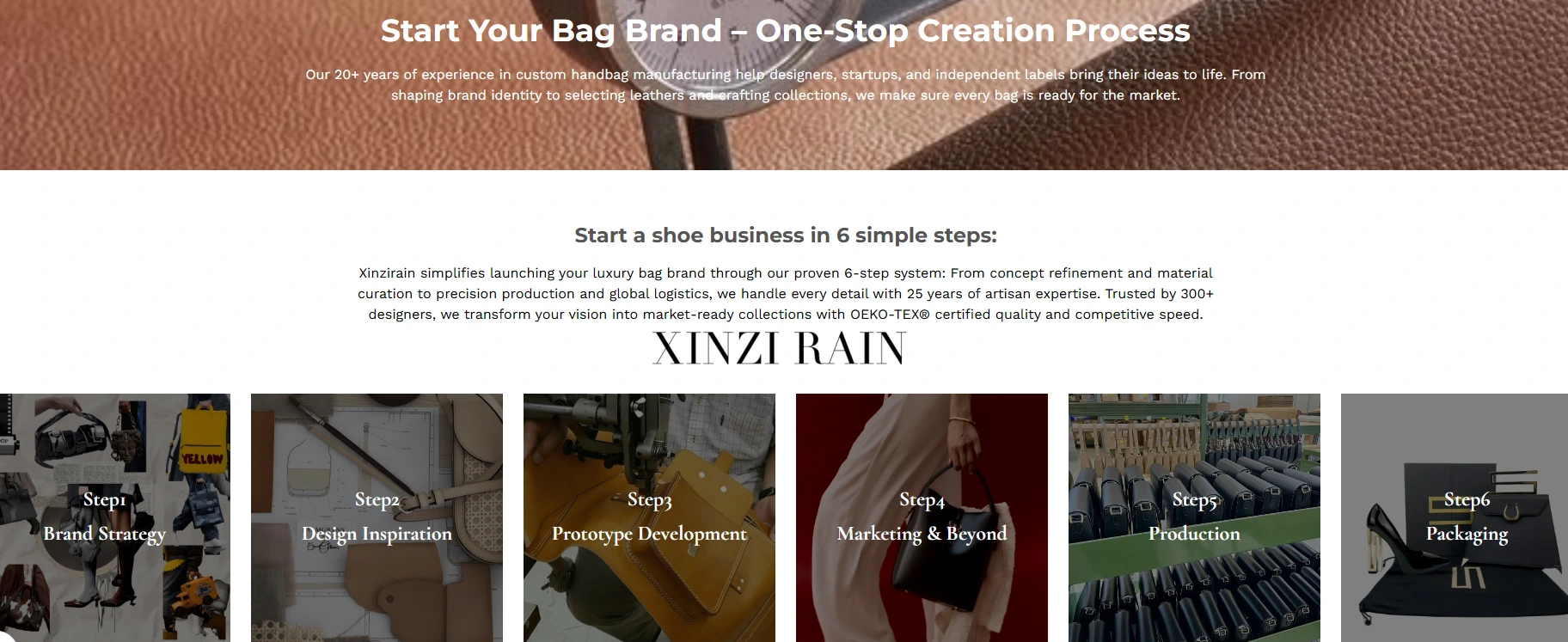

Hardware Production and Development with XINZIRAIN

XINZIRAIN provides a complete hardware development pipeline for global bag brands:

-

Concept & Sketch — clients share sketches, design references, or CAD drawings.

-

3D Modeling — our team prepares digital artwork and technical files.

-

Mold Development — molds created according to shape, size, and logo details.

-

Sample Production — sample hardware made with different plating options.

-

Mechanical Testing — durability tests such as salt spray, pull force, and colorfastness.

-

Mass Production & QC — consistent quality across batches with strict inspection.

Thanks to our long-term relationships with hardware plating factories, we can ensure stable quality, fast sampling, and competitive pricing.

How to Evaluate Hardware Quality Before Bulk Production

Brands should always conduct quality checks before placing a bulk order. Key evaluation points include:

-

Whether the hardware surface is smooth and free of defects

-

Plating thickness and resistance to fading

-

Weight consistency (important for luxury lines)

-

Strength and durability (pull tests, scratch tests)

-

Color matching between leather and hardware

-

Opening/closing smoothness of clasps

-

Rust resistance tested through salt spray

A professional hardware QC checklist helps prevent potential defects in final production.

Why Brands Choose XINZIRAIN as Their Bag Hardware and Bag Manufacturer

XINZIRAIN supports brands with:

-

Custom hardware development

-

High-level plating and finishing

-

One-stop OEM/ODM bag manufacturing

-

Professional pattern makers and sampling team

-

Cost optimization to fit different market tiers

-

Experience with luxury, mid-market, and fast-fashion clients

Our clients value our attention to detail, ability to control quality, and deep understanding of how hardware connects design with functionality.

Conclusion

Choosing the right hardware is essential for creating high-quality handbags. The right metal, finish, and structure not only influence durability but also define the aesthetic and market positioning of a brand. Whether you’re building a luxury line with brass or a lightweight collection with aluminum, understanding the differences helps you control cost while improving product value.

With custom hardware development, technical support, and full OEM/ODM capabilities, XINZIRAIN helps brands build collections that stand out—inside and out.

Stay Connected with XINZIRAIN

Stay inspired with the latest footwear trends, design insights, and manufacturing updates from XINZIRAIN — your trusted OEM/ODM shoe & bag manufacturer in China.

Follow us on social media for exclusive product previews, behind-the-scenes craftsmanship, and global fashion insights:

Join the XINZIRAIN community — where quality, creativity, and craftsmanship meet global fashion.