Introduction: Comfort Is Not Subjective — It Is Designed

In the footwear industry, “comfort” is often treated as a matter of personal feeling.

From an ergonomic perspective, this is a misunderstanding.

Comfort is not accidental.

It is the result of structure, biomechanics, materials, and testing working together.

Poorly designed shoes force the human body to compensate. At first, this shows up as friction, fatigue, or pressure points. Over time, it may lead to structural stress in the feet, knees, hips, and lower back. The problem is not fashion itself — the problem is design that ignores the human body.

At XINZIRAIN, we believe every category of footwear — not only high heels, but also flats, boots, loafers, sandals, and lifestyle shoes — can and should be engineered with ergonomics in mind.

This article explains how ergonomic footwear is designed and manufactured, step by step, from a professional perspective.

What Ergonomic Footwear Really Means

Ergonomic footwear is designed based on how the human body stands, walks, and distributes pressure.

The goal is not to eliminate load, but to manage it intelligently.

From an ergonomic standpoint, healthy footwear should:

-

Respect natural foot anatomy

-

Distribute pressure across the foot

-

Support posture and balance

-

Reduce long-term musculoskeletal strain

When these principles are ignored, the body adapts through compensation — often at the cost of foot health and comfort.

Understanding the Foot: The Foundation of Ergonomic Design

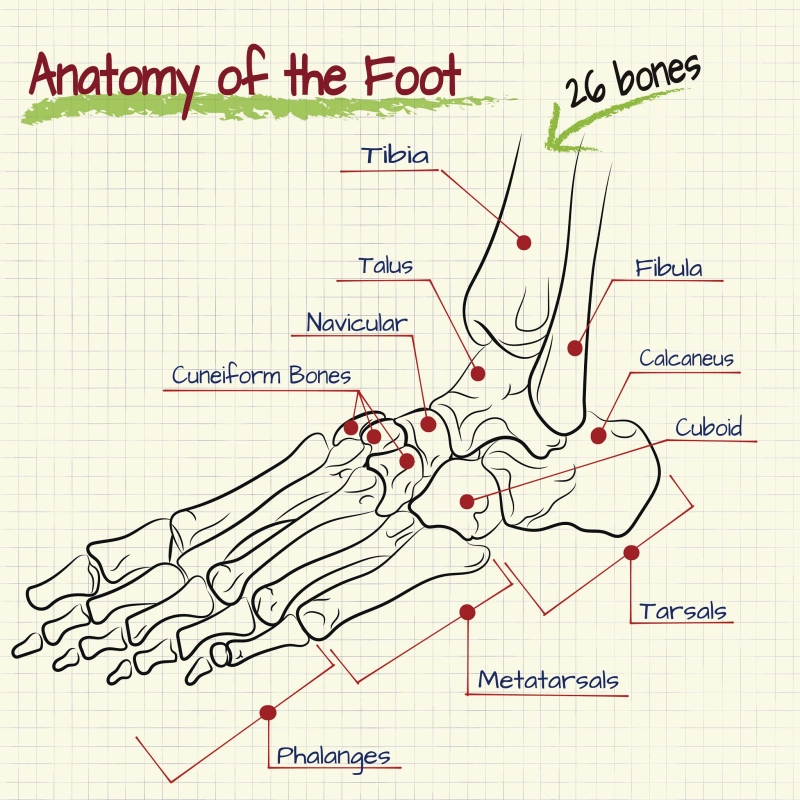

The foot is not a static object. It is a dynamic structure composed of:

-

Bones and joints

-

Muscles and tendons

-

Soft tissue and fascia

-

Natural arches that absorb shock and return energy

Effective ergonomic footwear design focuses on three fundamental objectives:

Structural Respect

The shoe must follow the foot’s natural shape rather than forcing it into an artificial form.

Pressure Distribution

Load should be shared between the heel, midfoot, and forefoot, instead of concentrating in one area.

Reduced Compensation

When balance and support are correct, the body does not need to “fight” the shoe while walking or standing.

Why Shoes Become Uncomfortable: The Real Causes

Most discomfort does not come from shoe height or appearance alone.

Common ergonomic failures include:

-

Inaccurate shoe lasts that do not match real foot shapes

-

Insufficient arch support

-

Poor heel positioning and instability

-

Toe boxes that compress the forefoot

-

Rigid insoles with no shock absorption

Two shoes with the same silhouette can feel completely different depending on how these factors are engineered.

The Shoe Last: The Core of Ergonomic Footwear

The shoe last is the anatomical foundation of every shoe.

It defines:

-

Length and width

-

Toe alignment

-

Arch curvature

-

Heel cup depth

-

Overall internal volume

In professional manufacturing, comfort problems are more often solved by millimetre-level adjustments to the last than by changing materials or adding padding.

For women’s footwear, especially, the last development is complex. Foot shapes vary widely by region, lifestyle, and age. A “standard size” rarely fits everyone.

Ergonomic footwear starts with precise last development, not decoration.

Toe Box Design: Elegance Without Compression

A common misconception is that refined or pointed shoes are inherently unhealthy.

In reality, the issue is not shape — it is compression.

An ergonomic toe box should:

-

Allow natural toe alignment

-

Provide sufficient internal volume

-

Minimise pressure on the big toe and forefoot

From a manufacturing perspective, this often means increasing internal volume without changing the external appearance — a balance that requires experience and precise pattern engineering.

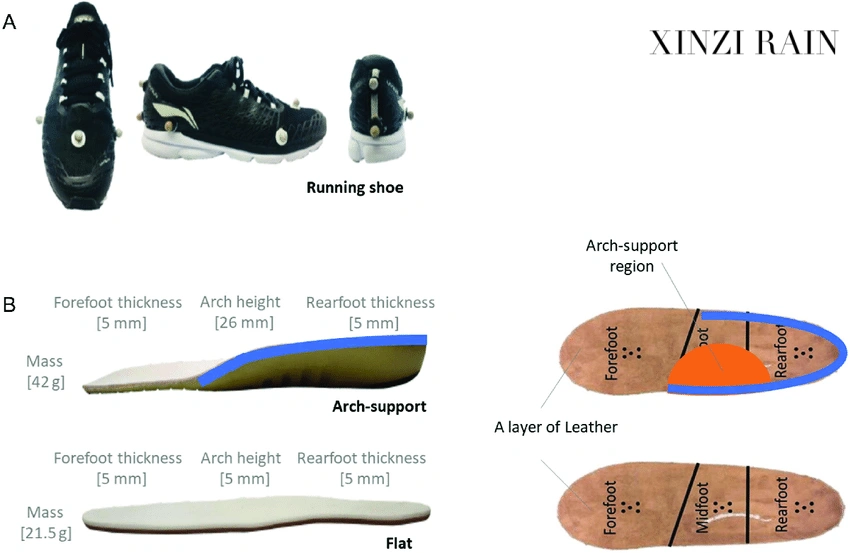

Arch Support & Midsole Engineering

The arch acts as the foot’s natural shock absorber.

Without proper support:

-

Forefoot pressure increases

-

Fatigue builds rapidly

-

Posture shifts upward to the knees and spine

However, “more support” is not always better.

Effective arch support must be:

-

Positioned correctly

-

Matched in firmness to the wearer’s needs

-

Integrated seamlessly with the last

In ergonomic footwear manufacturing, arch support is engineered — not added as an afterthought.

Heel Stability & Balance Control

Heel stability affects the entire kinetic chain.

Poor heel construction can lead to:

-

Slippage and friction

-

Forefoot overloading

-

Unstable gait

-

Increased stress on knees and hips

Ergonomic heel design focuses on:

-

Heel cup depth and curvature

-

Secure but non-abrasive support

-

Alignment with the body’s center of gravity

This applies to all footwear with structure — not only high heels.

Sole Flexibility: Bending Where the Foot Bends

A shoe should flex where the foot naturally flexes — near the metatarsal joints.

When flex points are misaligned:

-

Walking efficiency decreases

-

Muscle fatigue increases

-

Long-term discomfort becomes more likely

Softness alone does not guarantee comfort.

Correct flex positioning is essential.

Ergonomic Priorities by Footwear Category

Ergonomic design principles remain consistent, but priorities shift by category.

Athletic & Lifestyle Shoes

-

Shock absorption

-

Heel stability

-

Forefoot propulsion

-

Secure fit

Loafers, Dress Shoes & Flats

-

Heel retention

-

Arch support

-

Toe box volume

-

Breathable materials

Boots

-

Ankle mobility

-

Heel stability

-

Shaft friction control

-

Sole flexibility

Sandals & Open Shoes

-

Arch support

-

Heel cup stability

-

Forefoot grip

-

Weight balance

High-Heel Footwear

-

Center-of-gravity control

-

Forefoot pressure management

-

Hidden arch support

-

Structural heel stability

Height alone does not define health — engineering does.

Materials: Where Ergonomics Meets Skin Science

Ergonomic footwear is not only structural — it is also sensory.

Key material considerations include:

-

Breathability and moisture management

-

Friction control to prevent blisters

-

Cushioning durability over time

-

Controlled flexibility for natural movement

From a manufacturing standpoint, material choice directly affects long-term comfort, not just first wear.

Why Ergonomic Shoes Take Longer to Develop

At XINZIRAIN, one footwear style often requires six months of development.

This time is used for:

-

Last refinement

-

Multiple fitting rounds

-

Pressure feedback from real wear tests

-

Structural and balance adjustments

From cutting to final shaping, one pair typically takes seven days — not due to inefficiency, but because precision requires time.

This is how ergonomic intent survives mass production.

From Design to Mass Production: A Healthy Workflow

Professional ergonomic footwear development follows a structured process:

-

Target user analysis & foot data

-

Last development and iteration

-

Structural engineering (arch, heel, sole)

-

Material selection and testing

-

Multi-round wear trials

-

Production consistency control

Without this process, “ergonomics” becomes marketing language rather than reality.

A Practical Ergonomic Footwear Checklist (For Brands & Buyers)

When evaluating footwear or suppliers, ask:

-

Is the last designed for real foot anatomy?

-

Is arch support structural or cosmetic?

-

Does the heel provide true stability?

-

Does the sole flex at the correct point?

-

Is comfort consistent from sample to bulk?

These questions build trust and long-term product value.

Ergonomics as a Modern Expression of Respect

Designing shoes that respect the body is not a compromise — it is progress.

True quality allows:

-

Style without pain

-

Elegance without endurance

-

Expression without physical cost

In this sense, ergonomic footwear design is not only technical — it is ethical.

Conclusion: Turning Design into Long-Term Wearability

Great footwear should do more than look good.

It should support movement, protect health, and endure daily life.

At XINZIRAIN, our vision is to be a global fashion service leader, making every creative idea accessible to the world.

Our mission is to turn fashion dreams into commercial reality — without sacrificing comfort, health, or longevity.

When design respects the human body,

every step becomes more confident, more sustainable, and more meaningful.

FAQ: Ergonomic Footwear Design & Manufacturing

What is ergonomic footwear design?

Ergonomic footwear design focuses on aligning shoes with human anatomy and natural movement. It considers foot structure, pressure distribution, balance, and long-term comfort rather than appearance alone.

Are ergonomic shoes only for orthopaedic or medical use?

No. Ergonomic principles can be applied to all footwear categories, including fashion shoes, boots, flats, sandals, and high heels. Good ergonomics enhance wearability without compromising style.

Why do some shoes feel comfortable at first but painful after long wear?

Initial comfort often comes from soft materials, while long-term discomfort is usually caused by poor shoe lasts, lack of arch support, incorrect heel positioning, or pressure concentration during walking.

How important is shoe last development in ergonomic footwear?

The shoe last is the foundation of ergonomic footwear. It determines internal volume, toe alignment, arch curvature, and heel fit. Many comfort issues are solved through precise last adjustments rather than material changes.

Does heel height always affect foot health?

Heel height influences pressure distribution, but it is not the only factor. Heel position, forefoot cushioning, arch support, and overall balance are equally important in determining comfort and stability.

Can pointed-toe shoes be ergonomic?

Yes, if internal toe box volume allows natural toe alignment. Discomfort comes from compression, not shape. Well-designed pointed shoes can balance elegance and foot health.

What role does arch support play in footwear comfort?

Arch support helps distribute body weight and reduce forefoot pressure. Effective support must match foot anatomy and be integrated into the shoe structure rather than added superficially.

Why is heel stability important for overall posture?

Heel instability can alter gait, increase muscle fatigue, and transfer stress to knees and hips. Proper heel cups and structural support improve balance and walking efficiency.

How do materials affect ergonomic performance?

Breathability, flexibility, friction control, and cushioning durability directly influence comfort. Materials should support movement and maintain performance over time, not just feel soft at first wear.

Why does ergonomic footwear take longer to develop?

Ergonomic shoes require multiple rounds of last refinement, wear testing, and micro-adjustments. Development time ensures comfort consistency from prototype to mass production.

How can brands verify whether a shoe is truly ergonomic?

Brands should evaluate the last design, pressure distribution, flex points, heel stability, and wear-test feedback rather than relying on visual design or marketing claims alone.

Is ergonomic footwear design relevant for private label and OEM manufacturing?

Absolutely. For private label brands and OEM clients, ergonomic design improves product differentiation, reduces return rates, and builds long-term customer trust.