What Brands Should Know Before Choosing a Custom Athletic Shoe Manufacturer

Choosing the right upper materials is one of the most critical decisions in athletic shoe development. For brands, product managers, and sourcing teams, upper material selection directly impacts comfort, durability, performance, and long-term customer satisfaction.

At the same time, even the best materials will fail if the right athletic shoe manufacturer does not support them. This guide explores the key differences between running shoe uppers and training shoe uppers, and explains what brands should look for when selecting a custom athletic shoe manufacturer, especially when working with experienced manufacturers in China such as XINZIRAIN.

Why Upper Materials Matter in Athletic Footwear

In athletic shoes, the upper is responsible for more than just appearance. It plays a central role in:

-

Foot containment and stability

-

Breathability and moisture management

-

Weight control

-

Long-term durability under repeated motion

Running shoes and training shoes serve very different biomechanical purposes, which means their upper material requirements differ significantly.

Understanding these differences is the foundation of successful athletic shoe development.

Understanding the Difference Between Running Shoes and Training Shoes

Running Shoes: Linear Motion and Repetitive Impact

Running shoes are designed primarily for forward, repetitive motion. Key requirements include:

-

Lightweight construction

-

High breathability

-

Flexibility in the forefoot

-

Minimal lateral resistance

The upper must move naturally with the foot over thousands of repetitive steps without creating pressure points or overheating.

Training Shoes: Multi-Directional Movement and Stability

Training shoes are built for lateral movement, pivoting, and sudden directional changes. Their uppers must provide:

-

Enhanced side-to-side support

-

Greater abrasion resistance

-

Stronger structural integrity

-

Secure lockdown during dynamic movement

As a result, training shoe uppers typically prioritize stability and durability over ultra-lightweight construction.

Best Upper Materials for Running Shoes

Engineered Mesh: Lightweight and Breathable

Engineered mesh is one of the most widely used upper materials for running shoes.

Advantages

-

Excellent airflow and ventilation

-

Low weight

-

Flexible structure that adapts to foot movement

Considerations

-

Requires reinforcement in high-stress zones

-

Lower abrasion resistance compared to synthetic leather

Experienced manufacturers adjust mesh density and yarn structure to balance breathability with durability—an area where manufacturing expertise matters significantly.

Knit Uppers: Comfort with Controlled Support

Knit uppers offer a sock-like feel and seamless comfort.

Why brands choose knit

-

Reduced friction points

-

Adaptive fit

-

Premium consumer perception

However, knit uppers must be carefully engineered to prevent overstretching and loss of structure over time. This requires precise tension control and reinforcement during manufacturing.

Strategic Overlays in Running Shoes

Even lightweight running shoes require structural support. TPU films or thin overlays are often added to:

-

Improve midfoot lockdown

-

Increase durability

-

Maintain shape after extended wear

The key is using reinforcement selectively, without compromising flexibility or weight.

Best Upper Materials for Training Shoes

Synthetic Leather: Structure and Durability

Synthetic leather is commonly used in training shoes due to its:

-

High abrasion resistance

-

Structural stability

-

Ease of maintenance

It provides the firm support needed for lateral movements and high-impact training environments.

TPU and Reinforcement Systems

Thermoplastic polyurethane (TPU) overlays are widely used in training shoes to:

-

Enhance lateral stability

-

Prevent excessive upper deformation

-

Improve foot containment during explosive movements

This material is especially effective when integrated into well-designed shoe lasts and construction methods.

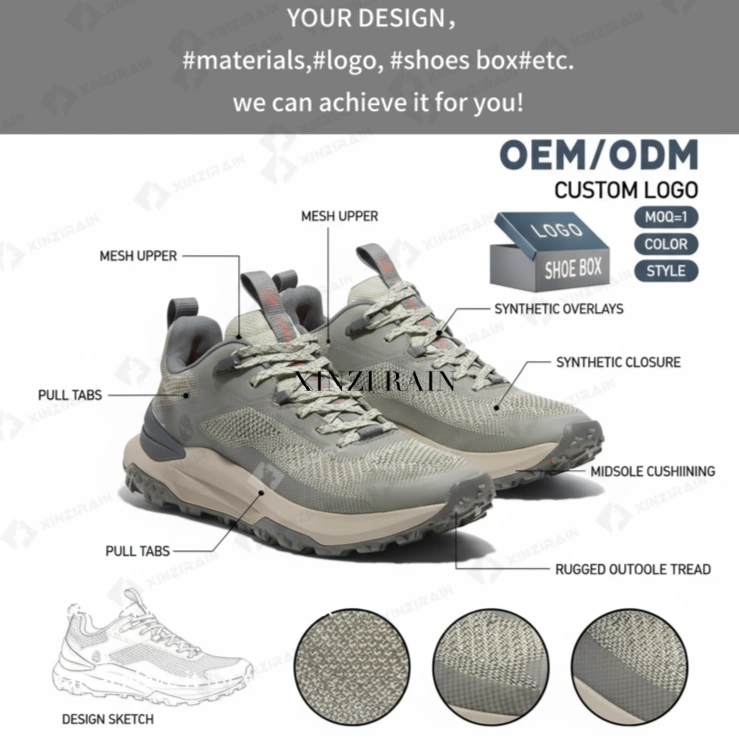

Hybrid Uppers: Mesh + Structure

Many modern training shoes use hybrid uppers that combine mesh panels with synthetic leather or TPU reinforcements.

This approach allows brands to balance:

-

Breathability

-

Support

-

Cost efficiency

Successful hybrid uppers depend heavily on manufacturing precision and material integration techniques.

Running Shoes vs Training Shoes: Upper Material Comparison

| Feature | Running Shoes | Training Shoes |

|---|---|---|

| Breathability | Very High | Moderate |

| Lateral Support | Low to Moderate | High |

| Durability | Moderate | High |

| Weight | Lightweight | Medium |

| Upper Structure | Flexible | Reinforced |

This comparison highlights why material decisions must align with intended use, not just aesthetics.

Common Mistakes Brands Make When Choosing Upper Materials

Many brands encounter issues during development due to avoidable mistakes, including:

-

Using running shoe materials in training shoes without reinforcement

-

Prioritizing lightweight design over functional stability

-

Ignoring long-term wear and deformation

-

Selecting materials without considering manufacturing feasibility

These mistakes often stem from a lack of collaboration between design teams and experienced athletic shoe manufacturers.

Why Upper Material Choice Is Closely Linked to the Manufacturer

Materials Alone Do Not Guarantee Performance

Two factories using the same materials can produce vastly different results. Performance depends on:

-

Cutting accuracy

-

Stitch density and consistency

-

Lamination and bonding techniques

-

Tension control during assembly

This is why choosing the right custom athletic shoe manufacturer is just as important as selecting the materials themselves.

Development Experience Matters More Than Material Lists

Many factories can provide a long list of available materials. Fewer have the experience to engineer those materials into functional athletic footwear.

Manufacturers with proven experience in athletic shoe development understand how materials behave under real-world movement and long-term wear.

What to Look for in a Custom Athletic Shoe Manufacturer

Proven Experience in Athletic Footwear Manufacturing

Not all sneaker factories are athletic shoe specialists. Brands should look for manufacturers with experience in:

-

Running shoes

-

Training shoes

-

Performance-focused construction

This distinction is critical for quality and consistency.

Shoe Last Development and Fit Expertise

Shoe lasts directly affect how upper materials perform.

A capable manufacturer should offer:

-

Multiple last options for different foot types

-

Gender-specific last development

-

Fit adjustments based on market feedback

Upper materials must work in harmony with the shoe last to deliver proper fit and performance.

Sampling and Upper Material Testing Capability

Professional athletic shoe manufacturers support:

-

Multiple sampling iterations

-

Material stress testing

-

Wear testing and fit evaluation

This process ensures the final product performs as intended before mass production.

Quality Control for Performance Shoes

Quality control in athletic footwear should include:

-

Bonding strength checks

-

Stitch consistency

-

Dimensional stability testing

Without structured QC systems, performance shoes often fail prematurely.

Customization and Scalability

Brands should consider whether a manufacturer can support:

-

Small-batch testing

-

Market validation

-

Scalable production for growth

Flexibility is especially important for emerging and growing brands.

Working with a Professional Athletic Shoe Manufacturer in China

China remains one of the world’s leading athletic footwear manufacturing hubs due to its mature supply chains and technical expertise.

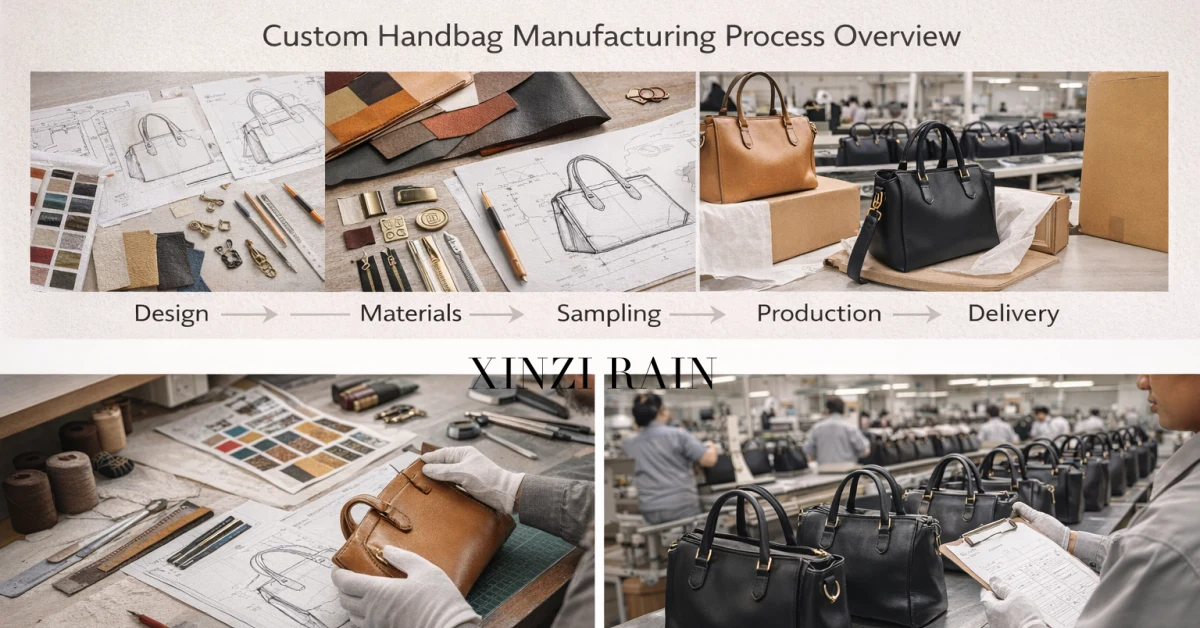

XINZIRAIN, a China-based custom athletic shoe manufacturer, works with international brands to develop running shoes and training shoes that balance performance, comfort, and manufacturability. With experience in material selection, shoe last development, sampling, and scalable production, XINZIRAIN supports brands throughout the entire development process—from concept to bulk manufacturing.

Final Thoughts

Choosing the right upper materials for running shoes and training shoes is a strategic decision that affects product performance, brand reputation, and long-term success.

However, materials alone are not enough. Brands must align material selection, shoe last design, and manufacturing expertise to create athletic footwear that performs consistently in real-world conditions.

By working with an experienced custom athletic shoe manufacturer like XINZIRAIN, brands can reduce development risk, improve product quality, and build scalable athletic shoe collections with confidence.

FAQ

What is the main difference between running shoe uppers and training shoe uppers?

Running shoe uppers prioritize lightweight breathability and flexibility for repetitive forward motion, while training shoe uppers focus on lateral support, durability, and structural stability for multi-directional movement.

Which upper material is best for running shoes?

Engineered mesh and knit uppers are commonly used for running shoes because they provide excellent breathability and lightweight comfort, often combined with targeted reinforcements for support.

Which upper materials are better for training shoes?

Training shoes typically use synthetic leather, TPU overlays, or hybrid uppers that combine mesh with structural reinforcements to ensure durability and lateral stability.

Why does the manufacturer matter when choosing upper materials?

Upper materials perform differently depending on cutting, stitching, bonding, and assembly techniques. An experienced athletic shoe manufacturer ensures materials deliver consistent performance and durability.

What should brands look for in a custom athletic shoe manufacturer?

Brands should evaluate experience in athletic footwear, shoe last development, sampling and testing capability, quality control systems, and scalability for long-term production.

Can one manufacturer handle both running shoes and training shoes?

Yes. Professional manufacturers like XINZIRAIN develop both running and training shoes by adjusting materials, shoe lasts, and construction methods to match specific performance requirements.