Introduction

For decades, “Made in Italy” has been synonymous with luxury, heritage, and exceptional craftsmanship. From premium leather footwear to refined designer handbags, Italy’s manufacturing reputation has shaped global fashion standards.

But behind the romanticized image lies a complex reality: Italian-made products are expensive—often extremely so—not only because of artisanal skills, but also due to high labor, energy, and operational costs.

At the same time, a new global trend is emerging: brands want Italian craftsmanship… without the Italian production price tag.

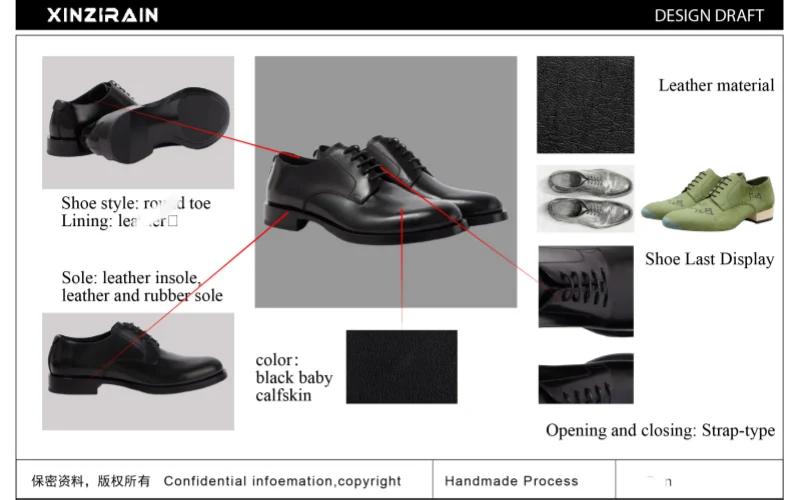

This is where XINZIRAIN, a leading Chinese fashion shoe and bag manufacturer, stands out. By combining Italian-inspired shoemaking methods, premium materials, and modern production systems, XINZIRAIN helps brands achieve the same craftsmanship look and feel—at significantly more efficient timelines and scalable costs.

In this article, we break down the true costs behind “Made in Italy” and explain how XINZIRAIN bridges the gap between European craftsmanship and high-efficiency global manufacturing.

The Craftsmanship Behind Italian Production — And Why It Costs More

Italy’s fashion heritage is built on artistry, family-owned workshops, and highly specialized skills. The heart of “Made in Italy” lies in:

1. Generational Craftsmanship

Italian shoemakers in regions like Tuscany and the Marche are known for techniques passed down through families—hand-lasting, hand-stitching, leather carving, finishing, and more.

2. High-Touch Production

Many steps in the Italian shoemaking process are purposely done by hand to preserve authenticity and texture—creating beautiful results but also longer timelines and higher labor costs.

3. Meticulous Quality Standards

Italian goods undergo strict finishing, inspection, and refinement. This is part of the charm, but it adds weeks or even months to production.

These details make Italian products exceptional—but also expensive and slow to produce.

Premium Raw Materials: A Core Cost Driver

Italy is famous for sourcing world-class raw materials—high-grade leather, metal hardware, textiles, and dyes. But these come at a premium:

Vegetable-tanned leather from Tuscany

Slow tanning cycles, eco-conscious processes, and artisanal finishing make Italian leather highly desirable but expensive.

Luxury textiles from Como

Italy’s silk and textile mills offer precision weaving and intricate dyes, increasing cost per meter.

Material traceability

A growing emphasis on sustainability and ethical sourcing adds additional overhead to already costly materials.

For many brands, these material costs alone make small-batch production in Italy financially challenging.

High Labor Costs and Long Timelines

Labor cost is one of the biggest contributors to Italian production prices:

-

Italy’s average labor cost: ~€27–30/hour

-

Portugal: ~€16/hour

-

China: ~€6–7/hour (skilled footwear manufacturing labor)

In addition:

Italian production cycles are slow

Luxury heels, leather boots, and complex handbags may require 60–180 days from development to delivery—too long for fast-moving brands or seasonal trends.

Small-batch orders often rejected

Many Italian factories prefer luxury quantities or brand-name clients, leaving newer brands with few options.

The Hidden Costs: Electricity & Operational Expenses

Few people realize that Italy has some of the highest industrial electricity rates in Europe. Energy-intensive steps—leather processing, molding, machining, stitching—become significantly more costly.

Combined with taxes, rent, and compliance costs, Italy’s operational overhead makes it difficult for emerging brands to scale production there.

Not All “Made in Italy” Is Actually Made by Italian Artisans

Due to legal loopholes and outsourcing, some Italian-labeled goods may involve:

-

overseas components

-

non-artisan labor

-

minimal finishing done in Italy

-

outsourced stitching, lining, and assembly

This creates inconsistency in quality and often leads brands to question whether they’re truly receiving authentic Italian craftsmanship.

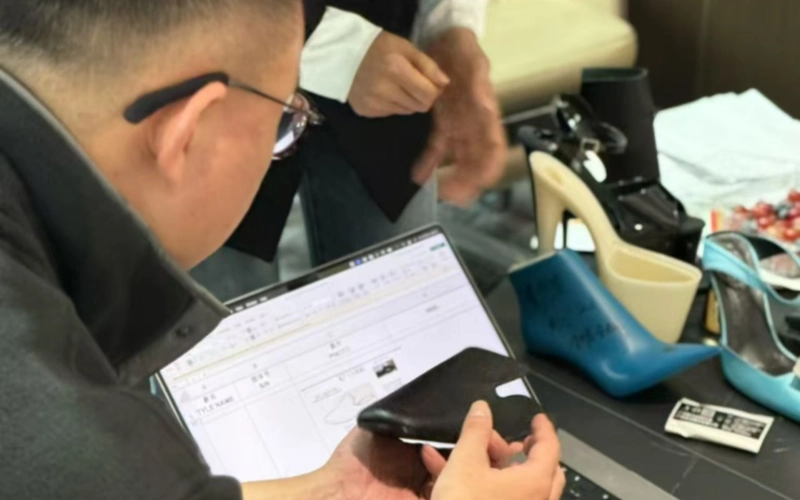

How XINZIRAIN Combines Italian Craftsmanship With Modern Chinese Efficiency

While Italy excels in heritage, China excels in innovation, efficiency, and flexible production models.

XINZIRAIN merges the best of both.

For over 20 years, XINZIRAIN has served global designers, boutiques, and European brands by delivering:

-

Italian-inspired shoemaking techniques

-

Premium leathers and high-end materials (imported and domestic options)

-

Strong design support from an in-house creative team

-

Faster sampling (7–12 days)

-

Lower MOQs starting from 100 pairs

-

Reliable mass production under strict quality control

Our Chengdu and Shenzhen factories follow many of the same artisanal principles as Italian workshops—last shaping, pattern cutting, hand-finishing, and leather craftsmanship—while maintaining the efficiency and scalability brands need today.

XINZIRAIN Advantage: Italian Technique, Modern Production

Italian-Inspired Shoemaking Processes

We integrate essential Italian craft elements including:

-

traditional cemented and stitched construction

-

premium leather cutting and folding

-

hand-polished finishing

-

artisanal edge treatments

-

elegant silhouette shaping

Brands achieve the “Italian aesthetic” at a far more competitive production cost.

Flexible for Small Designers and New Brands

Unlike many European factories, XINZIRAIN welcomes:

-

small MOQs

-

complex customized designs

-

trend-driven collections

-

long-term small-volume partnerships

Perfect for emerging designers, DTC brands, or boutique labels.

Faster Delivery Times

Where Italian factories may take 3–6 months, XINZIRAIN delivers:

-

Samples: 1–2 weeks

-

Bulk production: 25–40 days

-

Reorders: even faster

This speed allows brands to react to trends instead of missing seasons.

Sustainable & Transparent Production

XINZIRAIN invests in:

-

eco-friendly materials

-

low-waste cutting methods

-

traceable leather options

-

advanced energy-efficient machinery

Offering sustainability without the extreme cost premiums seen in Europe.

Competitive Pricing Without Compromising Luxury

By optimizing processes and leveraging China’s manufacturing ecosystem:

-

brands achieve higher margins

-

retail pricing becomes more accessible

-

production remains consistent across orders

This balance of quality and cost efficiency is one of XINZIRAIN’s strongest advantages.

Conclusion: Italian Craftsmanship Is Exceptional — But Not the Only Path to Luxury

The costs behind “Made in Italy” are real: high wages, expensive materials, long timelines, and elevated operational expenses. For heritage luxury brands, these costs may be justified.

But for modern emerging brands seeking:

-

quality craftsmanship

-

trend responsiveness

-

scalable production

-

faster lead times

-

accessible minimum orders

Italy is not always practical.

XINZIRAIN offers the solution.

By blending Italian shoemaking techniques with China's technological efficiency, XINZIRAIN helps brands create luxury-level footwear and bags—without the limitations of traditional European production.

FAQ

Why is “Made in Italy” so expensive?

Because of high labor costs, premium material sourcing, long production times, and elevated energy/operational expenses.

Can Chinese manufacturers match Italian craftsmanship?

Yes—when working with high-end factories like XINZIRAIN that specialize in artisanal processes, premium materials, and refined finishing.

Why work with XINZIRAIN instead of producing in Europe?

XINZIRAIN offers Italian-inspired craftsmanship, faster delivery, lower cost, flexible MOQs, and strong design support—ideal for brands that need efficiency without compromising quality.

Can XINZIRAIN support custom shoe designs?

Absolutely. Our design team helps with sketches, tech packs, materials, molds, branding, and full OEM/ODM development.

Is XINZIRAIN suitable for small designers or startups?

Yes—our low MOQs (starting at 100 pairs) and collaborative development approach are perfect for emerging brands.

Do you offer premium leather and sustainable options?

Yes. We provide imported Italian leather, domestic full-grain leather, vegan materials, recycled textiles, and eco-conscious production choices.

Stay Connected with XINZIRAIN

Stay inspired with the latest footwear trends, design insights, and manufacturing updates from XINZIRAIN — your trusted OEM/ODM shoe & bag manufacturer in China.

Follow us on social media for exclusive product previews, behind-the-scenes craftsmanship, and global fashion insights:

Join the XINZIRAIN community — where quality, creativity, and craftsmanship meet global fashion.