In an era dominated by sneakers, casual silhouettes, and fast-moving trends, one question continues to surface quietly among serious footwear brands: why do dress shoes—arguably the most traditional category—still rely so heavily on OEM manufacturing?

The answer is not about cost alone. It is about craftsmanship, control, consistency, and the ability to translate design intention into a product that lasts not just one season, but many years.

Dress shoes are slow products in a fast world. And that is precisely why OEM manufacturing still matters.

Dress Shoes Are Not Trend Products—They Are Reputation Products

Unlike sneakers, dress shoes are rarely impulse purchases. A customer buying a pair of Oxfords or loafers is not chasing novelty. They are buying confidence: confidence that the shoe will fit correctly, age beautifully, and still look appropriate years from now.

For brands, this changes everything.

A failed sneaker model can disappear next season. A poorly made dress shoe damages brand trust long after the launch window closes. Stitching precision, leather selection, sole construction, and shape retention are no longer aesthetic choices—they are brand signals.

This is where OEM manufacturing becomes essential. Not because brands lack creativity, but because dress shoes demand a level of production discipline that few ad-hoc or off-the-shelf solutions can provide.

What OEM Really Means in Dress Shoe Manufacturing

OEM manufacturing in dress shoes is often misunderstood as “outsourcing.” In reality, it is closer to co-development.

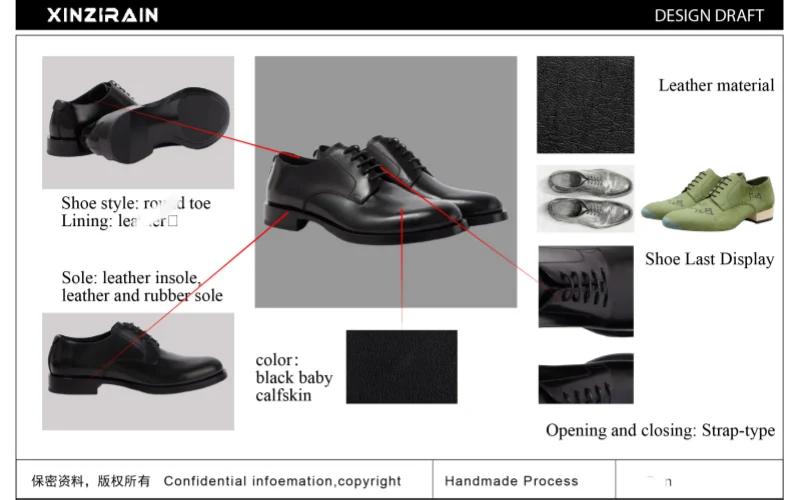

A capable OEM partner does not simply follow drawings. They interpret proportions, adjust patterns, refine lasts, and flag structural risks before they become expensive mistakes. In formal footwear, millimeters matter. A slight imbalance in toe shape or heel pitch can change how a shoe feels after eight hours of wear.

This is why established brands rarely switch dress shoe factories casually. Once the fit logic and construction philosophy are aligned, that relationship becomes part of the brand’s DNA.

Leather Choice Is a Strategic Decision, Not a Sourcing Detail

In dress shoes, leather is not decoration—it is structure.

Full-grain calfskin behaves differently from corrected grain. Vegetable-tanned leather ages differently from chrome-tanned alternatives. Eco-friendly leather introduces another layer of consideration: sustainability must not compromise form retention or longevity.

Experienced OEM manufacturers understand these trade-offs. They know which leathers soften too quickly, which crack under dry climates, and which adapt better to Middle Eastern heat or European humidity.

For brands exploring eco-friendly leather in dress shoes, this expertise becomes even more critical. Sustainability is not achieved by material labels alone, but by matching material behavior with design intent and expected lifespan.

Construction Methods Define How a Dress Shoe Lives Its Life

Goodyear welted shoes are often praised for durability and repairability, but they are not automatically the right choice for every brand. Blake construction offers elegance and flexibility but requires precise execution to avoid premature wear.

An OEM partner’s role is to help brands make these decisions strategically—not emotionally. The goal is not to copy heritage techniques blindly, but to select construction methods that align with price point, market expectation, and long-term brand positioning.

In this sense, OEM manufacturing is less about production volume and more about architectural thinking.

OEM Manufacturing Is Also About Risk Management

Dress shoes carry different risks than casual footwear. Returns are more expensive. Fit complaints are more damaging. Quality issues are harder to explain away.

A mature OEM manufacturer mitigates these risks through:

-

Stable pattern systems

-

Controlled material sourcing

-

Repeatable construction processes

-

Clear quality inspection standards

This operational stability allows brands to focus on storytelling, distribution, and customer relationships—without constantly firefighting production issues.

Where Sustainability Fits into Modern OEM Dress Shoes

Sustainable development in footwear is no longer optional. But in dress shoes, sustainability must be quiet, credible, and functional.

Eco-friendly leather, chrome-free tanning, and responsible sourcing only add value when they preserve the essential promise of dress shoes: longevity. A shoe that lasts ten years is often more sustainable than one that biodegrades in two.

OEM manufacturers who understand this balance help brands integrate sustainability without sacrificing performance. This is where sustainable development becomes practical, not performative.

Why Brands Work with Xinzirain

At Xinzirain, OEM manufacturing is approached as a long-term partnership rather than a transactional service. The focus is not just on making dress shoes, but on helping brands build collections that age well—technically, aesthetically, and commercially.

Xinzirain supports brands developing custom dress shoes, private label formal footwear, and eco-conscious collections by combining material expertise, pattern development, and production stability. The result is footwear that feels deliberate, not rushed.

Final Thought

Dress shoes survive because they respect time. OEM manufacturing survives in this category for the same reason.

If your brand is building formal footwear meant to last—physically and symbolically—the right OEM partner is not a shortcut. It is the foundation.

If you are exploring OEM dress shoes, eco-friendly leather, or a more sustainable approach to custom footwear, Xinzirain is ready to have that conversation.