When global fashion brands search for reliable production partners, one phrase appears again and again: handbag manufacturing hub China.

This is not a coincidence, nor is it purely about cost. China has earned its position as the world’s leading handbag manufacturing hub through decades of specialization, supply chain depth, technical expertise, and an unmatched ability to scale—from emerging designers to global luxury labels.

In this article, we explore why China remains the handbag manufacturing hub of the world, what truly sets it apart, and how modern brands can leverage this ecosystem responsibly and strategically.

The Rise of China as a Global Handbag Manufacturing Hub

China did not become the handbag manufacturing hub overnight. Its rise began with export-focused light manufacturing in the late 20th century, but quickly evolved into a sophisticated production ecosystem.

Today, the handbag manufacturing hub China represents far more than factories—it is a fully integrated industrial network combining:

-

Raw material sourcing

-

Hardware and accessory clusters

-

Skilled labor specialization

-

Advanced sampling and prototyping

-

Global logistics infrastructure

This vertical integration allows brands to move from concept to market with speed and control that few regions can match.

Complete Supply Chain Integration: China’s Core Advantage

One of the strongest reasons China is the leading handbag manufacturing hub is its complete and localized supply chain.

Within a single manufacturing region, brands can access:

-

Genuine leather, vegan leather, recycled, and bio-based materials

-

Metal hardware, zippers, chains, and logo plates

-

Packaging suppliers (boxes, dust bags, tags)

-

Printing, embossing, debossing, and coating services

In contrast, many other countries rely on imported components, increasing cost, risk, and lead time. In the handbag manufacturing hub of China, everything is physically close, reducing friction at every stage.

Skilled Craftsmanship at Industrial Scale

A common misconception in Western markets is that “Made in China” equals mass production only. In reality, the handbag manufacturing hub of China combines artisan-level skills with industrial consistency.

Many handbag factories employ workers who specialize in a single process for years:

-

Pattern cutting

-

Edge painting

-

Hand stitching

-

Structural reinforcement

-

Quality inspection

This specialization enables Chinese manufacturers to deliver luxury-grade handbags at scale, something few regions can replicate reliably.

Design-to-Production Speed That Global Brands Require

Speed-to-market is now a competitive necessity. One reason China remains the dominant handbag manufacturing hub is its ability to compress timelines without sacrificing quality.

Typical timelines in the handbag manufacturing hub of China include:

-

Sampling: 25–40 days

-

Sample revisions: 7–14 days

-

Bulk production: 30–45 days

This speed allows brands to respond quickly to trends, replenish bestsellers, and reduce inventory risk—key concerns for both DTC and wholesale brands.

Flexible MOQs for Emerging and Scaling Brands

Another major advantage of the handbag manufacturing hub in China is flexibility. Unlike traditional European factories that often require high minimums, many Chinese manufacturers support:

-

Low MOQ (50–100 pieces per style)

-

Mixed colors and materials

-

Gradual scaling across seasons

This makes the handbag manufacturing hub of China especially attractive to independent designers, startup brands, and boutique retailers entering the market.

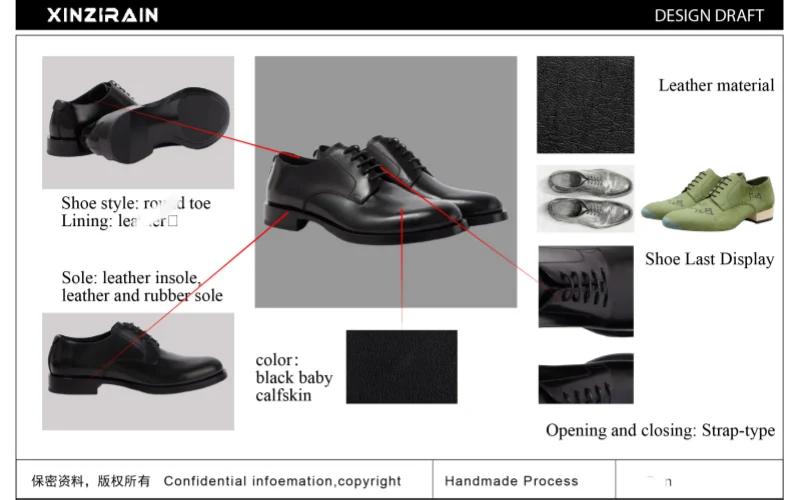

Advanced OEM and ODM Capabilities

China’s role as the handbag manufacturing hub extends beyond execution—it includes product development and design support.

Modern Chinese manufacturers provide:

-

OEM (your design, executed precisely)

-

ODM (concept development with in-house designers)

-

Technical feasibility reviews

-

Cost engineering and material optimization

For brands without large internal teams, the handbag manufacturing hub in China becomes an extension of their own product development department.

Quality Control Systems That Meet Global Standards

Quality perception has shifted dramatically over the past decade. Leading factories in the handbag manufacturing hub of China now operate under strict quality frameworks aligned with global markets.

These include:

-

Multi-stage in-line inspections

-

Final AQL-based quality checks

-

Compliance with EU REACH and US CPSIA standards

-

Traceability for leather and hardware sourcing

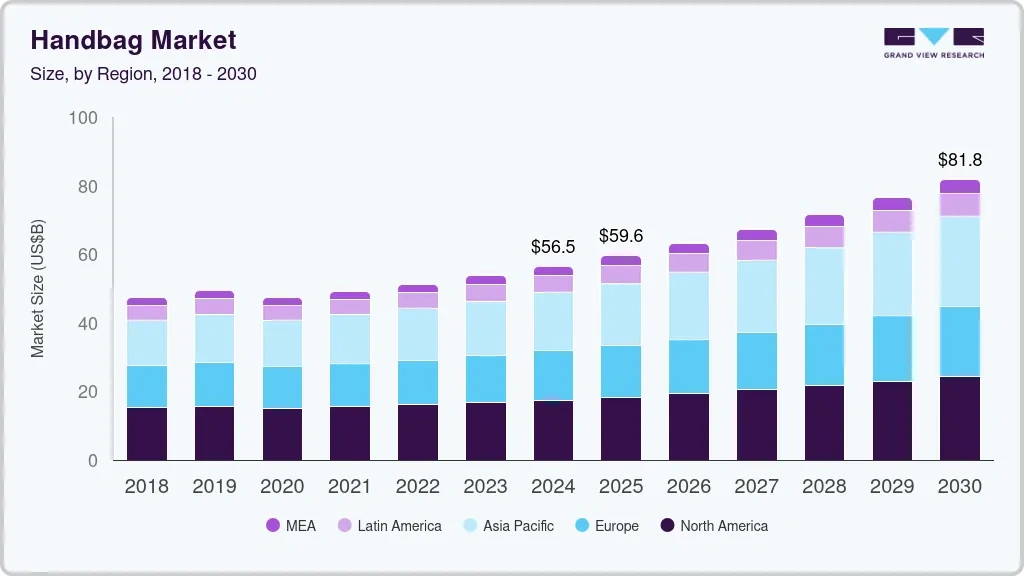

As a result, products from the handbag manufacturing hub of China regularly meet or exceed expectations in North America, Europe, the Middle East, and Japan.

Cost Efficiency Without Compromising Brand Value

While cost alone no longer defines success, cost efficiency remains a reason brands choose the handbag manufacturing hub of China.

Importantly, this efficiency is not just about low labor costs. It comes from:

-

Reduced logistics between suppliers

-

High production yields

-

Process optimization

-

Scalable labor allocation

For brands, this means better margins without cutting corners, a critical balance in today’s competitive fashion market.

Sustainability and Material Innovation in China

Sustainability is no longer optional. The modern handbag manufacturing hub China, has adapted quickly to global sustainability demands.

Many factories now offer:

-

LWG-certified leather

-

Recycled nylon and PU alternatives

-

Bio-based and plant-based leather options

-

Reduced-waste cutting processes

This evolution ensures that brands can pursue sustainability goals while still benefiting from China’s manufacturing scale.

Why Global Brands Continue to Choose China

Despite discussions about supply chain diversification, China remains the handbag manufacturing hub for brands that value reliability, control, and growth.

Global brands continue to manufacture in China because:

-

The ecosystem is proven and resilient

-

Production risks are lower due to experience

-

Innovation cycles are faster

-

Long-term partnerships are possible

In short, no other region currently offers the same balance of scale, flexibility, craftsmanship, and speed as the handbag manufacturing hub of China.

Xinzirain’s Role Within the Handbag Manufacturing Hub in China

At Xinzirain, we operate fully inside the handbag manufacturing hub of China, but with a different mindset.

Our approach is client-first and value-driven:

-

We begin by understanding your brand positioning and market goals

-

We provide design and material guidance before sampling

-

We support production with transparent communication

-

We continue to assist after launch, offering feedback and optimization suggestions

For us, manufacturing is not the finish line—it is part of a long-term partnership. We believe that when our clients succeed in the market, we succeed as manufacturers.

Conclusion: The Strategic Power of the Handbag Manufacturing Hub in China

China is the world’s leading handbag manufacturing hub, not because it is cheap, but because it is complete.

The handbag manufacturing hub in China offers brands:

-

End-to-end supply chain integration

-

Skilled craftsmanship at scale

-

Speed, flexibility, and reliability

-

Global compliance and sustainability options

For brands seeking to build long-term value—not just short-term production—the handbag manufacturing hub China remains the most strategic choice.

Thinking About Producing Handbags in China?

If you are exploring production within the handbag manufacturing hub of China and want a partner who understands both manufacturing and brand growth, Xinzirain is ready to support you.

Start your handbag project with Xinzirain

Explore OEM & ODM handbag manufacturing

Discuss materials, MOQ, and timelines with our team