Building your own shoe brand is no longer reserved for global fashion houses or venture-backed startups. Today, independent designers, lifestyle brands, streetwear labels, and even content creators are launching successful footwear brands by leveraging custom shoe manufacturers, flexible supply chains, and data-driven brand positioning.

This in-depth guide breaks down how to create your own shoe brand, from early concept validation to manufacturing execution and long-term scaling—based on real production logic, not theory.

Prelude: Why Creating a Shoe Brand Is Different from Selling Shoes

Many entrepreneurs confuse selling shoes with building a shoe brand.

The difference lies in ownership, differentiation, and scalability.

A true shoe brand controls:

-

Product identity

-

Manufacturing decisions

-

Quality standards

-

Long-term iteration capability

This is why choosing the right custom shoe manufacturer is not a tactical decision—it is a strategic one.

Creating your own shoe brand means designing a system that can repeatedly deliver consistent products, not just launching a single model.

Foundation: Defining Your Shoe Brand Positioning Before Manufacturing

Before contacting a factory, successful founders answer four non-negotiable questions:

Who Is Your Target Customer?

-

Gender / age range

-

Lifestyle (streetwear, luxury, comfort, outdoor, workwear)

-

Price tolerance

What Problem Does Your Shoe Brand Solve?

-

Fit issues (wide feet, arch support, size inclusivity)

-

Aesthetic gaps (underrepresented design language)

-

Functional needs (travel, standing all day, durability)

What Category Will You Start With?

Most scalable shoe brands start narrow:

-

Sneakers

-

Loafers

-

Clogs

-

Boots

-

Flats

This clarity directly affects custom shoe manufacturing costs, MOQ, and material selection.

Design Development: Turning Ideas into Production-Ready Footwear

Concept to Technical Design

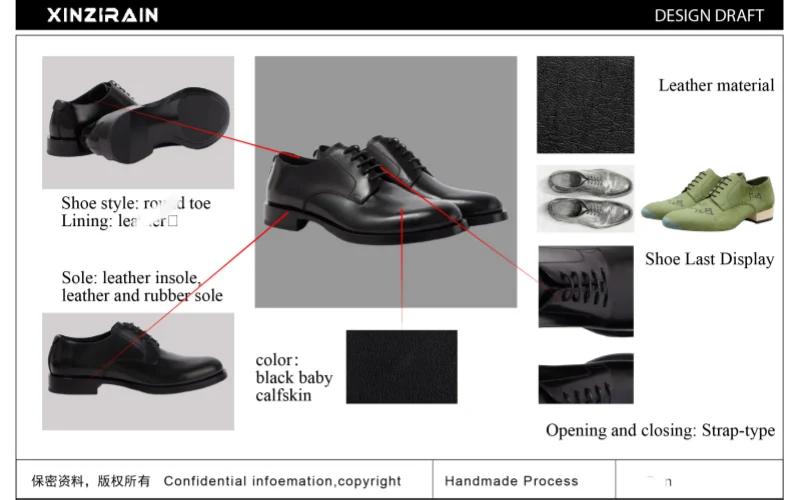

A shoe brand cannot rely on visuals alone. Manufacturers require:

-

Technical drawings

-

Reference shoes

-

Material preferences

-

Target cost range

This is where many first-time founders fail—design must be manufacturable, not just attractive.

Last Development: The Core of Shoe Comfort

The shoe last determines:

-

Fit

-

Arch support

-

Toe shape

-

Overall wearing experience

Professional custom shoe manufacturers in China develop or modify lasts to match your brand’s comfort standard, not copy competitors blindly.

Manufacturing Logic: How Custom Shoe Production Really Works

Material Selection

Choices impact brand perception and cost:

-

Full-grain leather vs suede

-

Vegan leather vs bio-based alternatives

-

Rubber, EVA, or cork soles

High-quality shoe manufacturers help brands avoid material mismatches that cause returns or complaints.

Cutting, Stitching, and Assembly

Consistency matters more than speed.

A reliable custom shoe factory focuses on:

-

Stitch density

-

Reinforcement points

-

Shape retention after wear

Quality Control Is a Brand Asset

100% inspection is not optional for premium brands.

Quality control protects your reputation before marketing ever begins.

Scaling from Samples to Bulk Production

Sampling Is a Learning Process

Expect:

-

1–3 sample revisions

-

Material adjustments

-

Fit refinement

This stage defines whether your shoe brand survives its first launch.

MOQ Strategy for New Shoe Brands

Modern custom shoe manufacturers in China often support:

-

Low MOQ (100–300 pairs per style)

-

Mixed size runs

-

Color testing

This flexibility allows brands to validate demand before scaling.

Packaging, Branding, and Market Readiness

Your shoe brand is judged before the shoes are worn.

Professional brands align:

-

Shoe boxes

-

Dust bags

-

Hang tags

-

Brand storytelling

Packaging is part of perceived value, especially in DTC and boutique retail channels.

Market Feedback: Why Long-Term Shoe Brands Think Beyond Production

Successful founders track:

-

Return reasons

-

Fit complaints

-

Wear patterns

-

Customer reviews

This data feeds directly back into:

-

Design iteration

-

Material upgrades

-

Next-season development

A true custom shoe manufacturing partner supports this feedback loop, not just production.

Why Choosing the Right Custom Shoe Manufacturer Matters

Not all factories are brand builders.

A strategic custom shoe manufacturer offers:

-

Brand positioning guidance

-

Design feasibility analysis

-

Cost-performance optimization

-

Long-term production planning

This is the difference between a supplier and a partner.

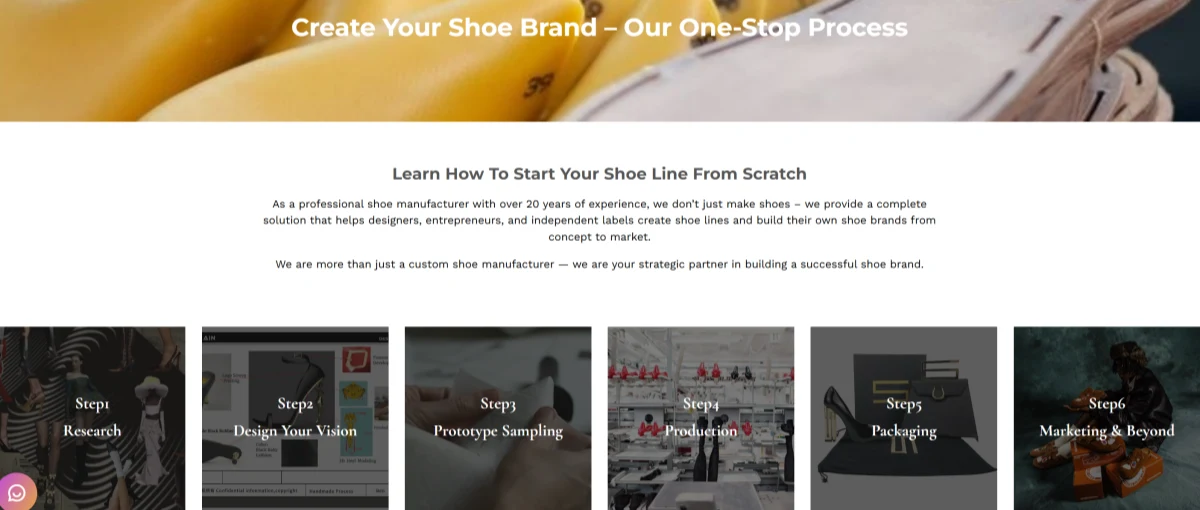

Create Your Own Shoe Brand with Xinzirain

At Xinzirain, we work with founders, designers, and growing brands who want more than a factory—they want a system.

Our approach to custom shoe manufacturing is built on a client-first, value-sharing mindset:

-

We research your brand positioning before production

-

We provide design and material guidance aligned with your market

-

We follow your product launch and market feedback

-

We optimize future production based on real performance

Because when your shoe brand wins in the market, our partnership succeeds long-term.

Final Thoughts: Building a Shoe Brand Is a Process, Not a Shortcut

Creating your own shoe brand is not about chasing trends—it’s about building repeatable value.

With the right strategy, the right custom shoe manufacturer, and a long-term mindset, independent brands can compete globally without massive upfront risk.

If you’re serious about creating your own shoe brand, the process starts with the right foundation.

Ready to Create Your Own Shoe Brand?

Work with a professional custom shoe manufacturer in China that understands branding, not just production.

Talk to Xinzirain about your shoe brand idea

Develop samples aligned with your market

Scale with confidence, clarity, and control