In today’s competitive footwear market, design alone is no longer enough. What separates premium brands from disposable products is structure. And that structure begins with shoe last development and advanced insole engineering.

At XINZIRAIN, we work as a long-term footwear manufacturer for EU and US brands that understand that durability, fit consistency, and customer retention all start from the inside.

If you are searching for a reliable footwear manufacturer, understanding the importance of professional shoe last development is critical.

Why Shoe Last Development Determines Market Success

Shoe last development defines the 3D structure of a shoe. The last controls:

-

Toe shape

-

Arch height

-

Heel balance

-

Width grading

-

Overall anatomical alignment

Many factories rely on generic molds to reduce cost. However, insufficient shoe last development often results in:

-

Inconsistent sizing

-

Customer discomfort

-

Uneven outsole wear

-

High return rates

Professional shoe last development ensures your footwear line maintains structural stability from sample stage to bulk production.

For B2B buyers, this directly impacts reorder rates and brand reputation.

Our Approach to Professional Shoe Last Development

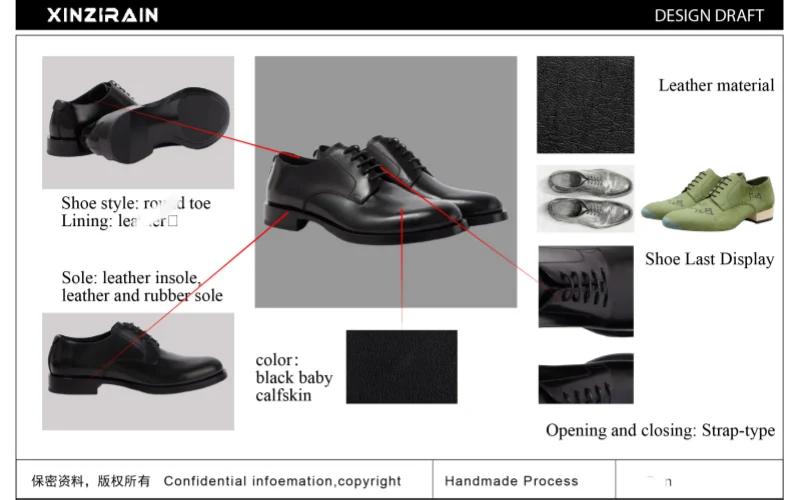

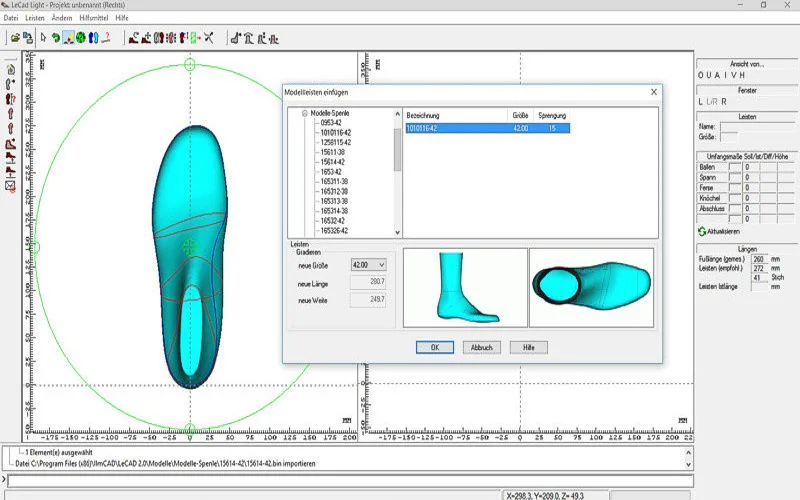

As an export-focused footwear manufacturer, XINZIRAIN invests heavily in customized shoe last development.

Our shoe last development process includes:

-

Regional fit analysis (EU / US sizing)

-

Heel pitch calibration

-

Toe box volume adjustment

-

Wear-test correction

-

Structural balance validation

For high heels, precise shoe last development determines comfort at 8–10cm heights.

For sneakers, accurate shoe last development ensures gait stability and fatigue reduction.

Without professional shoe last development, long-term comfort is almost impossible.

Why Insole Engineering Matters Just as Much

While shoe last development defines external structure, insole engineering defines internal performance.

Mass production often uses flat, low-density insoles. However, structured insole engineering improves:

-

Arch support

-

Heel stability

-

Shock absorption

-

Pressure distribution

At XINZIRAIN, our insole engineering adapts to the product category:

-

High heels → Forefoot cushioning + balance control

-

Sneakers → Energy return + multi-density layering

-

Boots → Anti-fatigue heel reinforcement

-

Dress shoes → Structural stability + comfort foam

Effective insole engineering reduces return rates and increases customer satisfaction — a crucial advantage for any footwear manufacturer serving Western markets.

Shoe Last Development + Insole Engineering = Structural Precision

The real strength of a professional footwear manufacturer lies in combining:

✔ Advanced shoe last development

✔ Performance-focused insole engineering

✔ Controlled prototype refinement

✔ Scalable production stability

During sampling, we continuously adjust shoe last development parameters and refine insole engineering details until structural balance is confirmed.

This integrated approach ensures that:

-

Samples match bulk production

-

Fit remains consistent across sizes

-

Comfort standards meet EU and US expectations

For private label brands, investing in shoe last development reduces long-term operational risk.

Why EU & US Brands Prioritize Structural Manufacturing

European and American markets emphasize:

-

Ergonomic fit

-

Durability

-

Consumer trust

-

Long-term value

Brands that collaborate with a footwear manufacturer specializing in shoe last development and insole engineering gain:

-

Lower return ratios

-

Stronger distributor confidence

-

Better repeat orders

-

Sustainable brand growth

Shoe last development is not a minor technical step. It is the foundation of scalable footwear manufacturing.

Manufacturing Is a Structural Strategy

If you are evaluating a footwear manufacturer, ask:

-

Do they invest in shoe last development?

-

Do they refine insole engineering?

-

Do they test structural balance before mass production?

-

Do they support private label customization?

At XINZIRAIN, shoe last development and insole engineering are not optional — they are the core of our manufacturing philosophy.

Because structure defines comfort.

Comfort defines reputation.

Reputation defines longevity.

Partner With a Footwear Manufacturer Focused on Structure

If your brand is looking for a footwear manufacturer that understands the strategic importance of shoe last development and advanced insole engineering, we are ready to support your next collection.

FAQ

What is the shoe last development in footwear manufacturing?

Shoe last development is the process of designing and refining the three-dimensional mold that defines a shoe’s shape, structure, and fit. Professional shoe last development ensures accurate sizing, structural balance, and long-term comfort in mass production.

Why is shoe last development important for private label brands?

For private label brands, shoe last development ensures a consistent fit across bulk orders. Without proper shoe last development, brands may face complaints about sizing, high return rates, and customer dissatisfaction.

How does insole engineering improve shoe comfort?

Insole engineering improves arch support, cushioning, and shock absorption. Advanced insole engineering distributes pressure evenly and enhances stability, especially in high heels, sneakers, and boots.

What is the difference between mass production lasts and custom shoe last development?

Mass production often uses generic molds, while custom shoe last development tailors the structure to a specific design or target market. Custom shoe last development improves anatomical alignment and long-term wearability.

Can a footwear manufacturer modify an existing shoe last?

Yes. A professional footwear manufacturer can adjust heel pitch, toe box volume, width grading, and arch positioning through shoe last development refinement during the prototype stage.

How does insole engineering reduce product returns?

Proper insole engineering enhances comfort and structural support, which reduces customer complaints related to foot fatigue, instability, and poor cushioning — common causes of product returns.

Is shoe last development necessary for high heels?

Absolutely. In high heels, precise shoe last development determines weight distribution and balance. Even small structural deviations can significantly impact long-term comfort and stability.

How long does custom shoe development take?

Custom shoe last development typically requires prototype testing and refinement. Depending on complexity, development can take 2–4 weeks before bulk production approval.

Why do EU and US brands focus on insole engineering?

EU and US markets emphasize ergonomic comfort and durability. Insole engineering helps brands meet these expectations while reducing liability risks associated with poor footwear construction.

What should brands look for in a footwear manufacturer?

Brands should choose a footwear manufacturer that invests in professional shoe last development, advanced insole engineering, controlled sampling processes, and scalable quality control systems.