In today’s leather goods market, few topics create more confusion than the difference between genuine leather, vegan leather, and various “leather-like” materials.

Misleading terminology, inconsistent labeling, and marketing-driven narratives often blur the line between what leather truly is—and what it is not.

Understanding leather correctly is not only important for consumers, but essential for brands, designers, and buyers who want to build products with lasting value.

This guide explains the types of leather, how to choose the right material, and how proper care directly affects product lifespan.

What Is Genuine Leather?

Genuine leather comes from a natural, organic source—animal hide.

Common sources include cow, buffalo, goat, pig, sheep, and specialty hides such as ostrich, snake, or alligator.

What makes genuine leather unique is that it is a living material:

- It breathes

- It reacts to environment and use

- It develops character over time rather than degrading immediately

Unlike synthetic materials, genuine leather ages, rather than simply wearing out.

Understanding Common “Leather” Categories (and What They Really Mean)

Not all materials labeled as “leather” are equal. Below is a clear, industry-based breakdown.

Bi-Cast Leather

Bi-cast leather is made by coating split leather with a polyurethane or polyethylene layer.

- Contains real leather (from lower hide layers)

- Coating adds surface strength and uniform appearance

- Limited breathability

- Surface layer may crack or peel over time

Used often in furniture or lower-cost accessories.

Bonded Leather

Bonded leather is created by grinding leather scraps into pulp and binding them together with adhesives.

Does not come from a single hide

Minimal structural integrity

Primarily used for bookbinding or decorative applications

Not suitable for high-quality footwear or handbags

From a strict industry perspective, this is not true leather.

PU Leather

PU “leather” is a synthetic material made by coating fabric (polyester, cotton, or nylon) with polyurethane.

- 100% man-made

- No leather content

- Limited breathability

- Prone to cracking and peeling

Despite the name, PU leather is more accurately described as PU fabric.

PVC Leather

PVC leather uses a polyvinyl chloride coating applied to fabric.

- Fully synthetic

- Heavier and less flexible than PU

- Lower environmental friendliness

- Tends to stiffen and degrade with age

Again, this material contains zero leather.

Vegan Leather: A Clarification

Vegan leather is a broad marketing term. In most cases, it refers to PU or PVC-based synthetic materials.

While vegan leather avoids animal content, it is important to understand:

- It does not age like genuine leather

- It deteriorates over time

- It does not develop patina or improve with use

From a material science standpoint, vegan leather is synthetic fabric, not leather.

Why Material Choice Matters for Product Longevity

One fundamental truth separates genuine leather from all alternatives:

All synthetic materials deteriorate. Genuine leather evolves.

With proper care, genuine leather:

- Softens instead of cracking

- Develops patina instead of peeling

- Retains structural integrity for decades

This is why high-quality leather footwear and handbags are often passed down or restored—something synthetic materials cannot achieve.

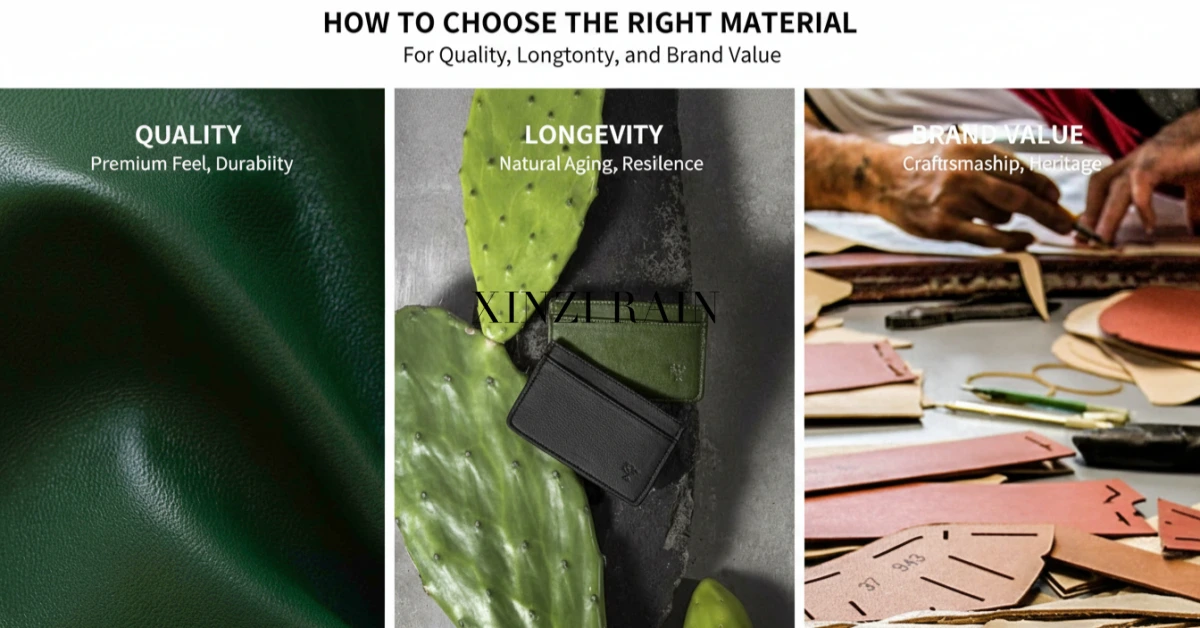

How to Choose the Right Leather for Shoes and Handbags

Choosing leather should be based on use case, brand positioning, and customer expectations, not just price.

For Premium Footwear

- Full-grain or top-grain leather

- Strong fiber structure for creasing resistance

- Breathability for comfort

- Compatibility with resoling and repair

For High-End Handbags

- Full-grain or corrected-grain leather

- Consistent thickness

- Good edge finishing performance

- Ability to hold structure without excessive reinforcement

For Entry-Level or Trend Products

- Carefully selected PU may be acceptable

- Clear customer communication is essential

- Shorter product lifespan should be expected

Leather Care: How to Extend Product Life

Material quality alone is not enough—care determines longevity.

Basic Leather Care Principles

- Avoid excessive moisture or heat

- Clean with soft cloth, not alcohol-based products

- Condition leather periodically to maintain flexibility

- Store with shape support (shoe trees, bag stuffing)

Why Leather Improves With Use

Leather fibers relax gradually with movement, allowing:

- Natural molding to foot or hand

- Surface patina formation

- Increased comfort and character

Synthetic materials lack this fiber structure and therefore degrade instead of adapting.

Why Manufacturing Expertise Matters

Even the best leather can fail if handled improperly.

Professional leather manufacturing ensures:

- Correct leather selection for each product component

- Proper cutting direction aligned with fiber structure

- Balanced reinforcement to prevent stress damage

- Finishing processes that protect, not suffocate, the leather

This is why brands working with experienced manufacturers consistently outperform those relying on material labels alone.

Choosing the Right Leather Starts With the Right Manufacturing Partner

Understanding leather is only the first step.

The real difference between a product that merely looks good and one that lasts for years lies in how that leather is selected, handled, and transformed through manufacturing.

At Xinzirain, leather is never treated as a generic material.

As a professional shoe and handbag manufacturer, we work with brands using a client-first and value-sharing mindset. Every project begins with understanding the brand’s positioning, target market, and design intention—because the right leather choice should always serve a clear commercial and aesthetic purpose.

Our one-stop manufacturing service includes:

- Early-stage guidance on leather selection based on product type, price positioning, and usage scenarios

- Technical evaluation of leather performance for footwear and handbag construction

- Controlled cutting, stitching, and finishing processes to preserve leather integrity

- Ongoing support after production, including feedback on market performance and product optimization

We believe manufacturing does not end at delivery.

Once a product enters the market, we continue to follow our clients’ launches, marketing strategies, and customer feedback—offering practical solutions that help brands refine future collections and reduce costly material or design mistakes.

In leather goods, quality is cumulative. It is built through correct material knowledge, skilled craftsmanship, and long-term thinking. At Xinzirain, our success is directly tied to our clients’ success—because only when our partners win in the market do we truly win as a manufacturer.

If you are looking to build a footwear or handbag brand based on authentic materials, honest craftsmanship, and sustainable quality, choosing the right leather—and the right manufacturing partner—makes all the difference.