The Rising Popularity of American Work Boots

In recent years, American work boots have become a global trend. Brands like Red Wing 875, Dr. Martens, and Timberland have captured mainstream attention, while more niche, professional bootmakers such as Wesco, White’s Boots, Viberg, Clinch, Julian, and Japan’s De Yong Sheng Ye are gaining a growing following among boot enthusiasts.

The author’s own pair of Red Wing 875s, purchased in 2016, still serves as a faithful companion — a testament to the enduring quality that defines well-crafted work boots.

Unlike most modern sneakers or casual shoes, work boots are made from real leather uppers and rely on traditional stitched constructions to connect the sole and the upper. Among these, the term “Goodyear Welt” has become synonymous with durability and craftsmanship — often praised as “more expensive, more complex, and far more durable — no delamination, resoleable, and wearable for ten years or more.”

Yet few truly understand what the Goodyear welt structure entails — or that it is only one of many traditional methods of attaching soles to uppers.

A Glimpse at Traditional Footwear Construction Methods

Beyond the Goodyear Welt and Hand Welt methods, other well-known constructions include:

-

Stitchdown & Veldtschoen, commonly used in heavy-duty work boots.

-

Norwegian Welt, seen in outdoor and dress shoes.

-

Blake Stitch, a hallmark of Italian shoemaking.

-

Fiddle-Back Waist, found in high-end bespoke footwear.

This article is the first in the

, covering Hand Welt, Goodyear Welt, and their derived techniques.

Modern Adhesive & Injection-Molded Constructions

Most modern footwear — such as sneakers and casual shoes — is made using cemented (adhesive) construction. The process is relatively simple: the upper is stitched and shaped on a last, the outsole is molded separately, and both are joined with strong synthetic adhesives.

Thanks to advances in resin-based glues, these bonds are quite strong. However, traditional adhesives often contain toxic organic solvents. Modern brands like Converse and Vans now use eco-friendly adhesives, but these tend to sacrifice some bonding strength — leading to the occasional “sole separation” issue familiar to many wearers.

To address this, brands like Nike reinforce their cemented shoes with additional stitching — for example, the Air Force 1 features visible stitches connecting the sole and the upper, reducing the risk of detachment.

Another popular process is direct-injection molding, where the melted sole material is injected directly into a mold beneath the upper, creating a seamless bond as it cools and hardens. This method minimizes delamination and is common in safety boots, outdoor shoes, and industrial footwear, such as Timberland’s yellow boots and Red Wing Supersole products.

Hand Welt Construction — The Origin of the Craft

Historical Background

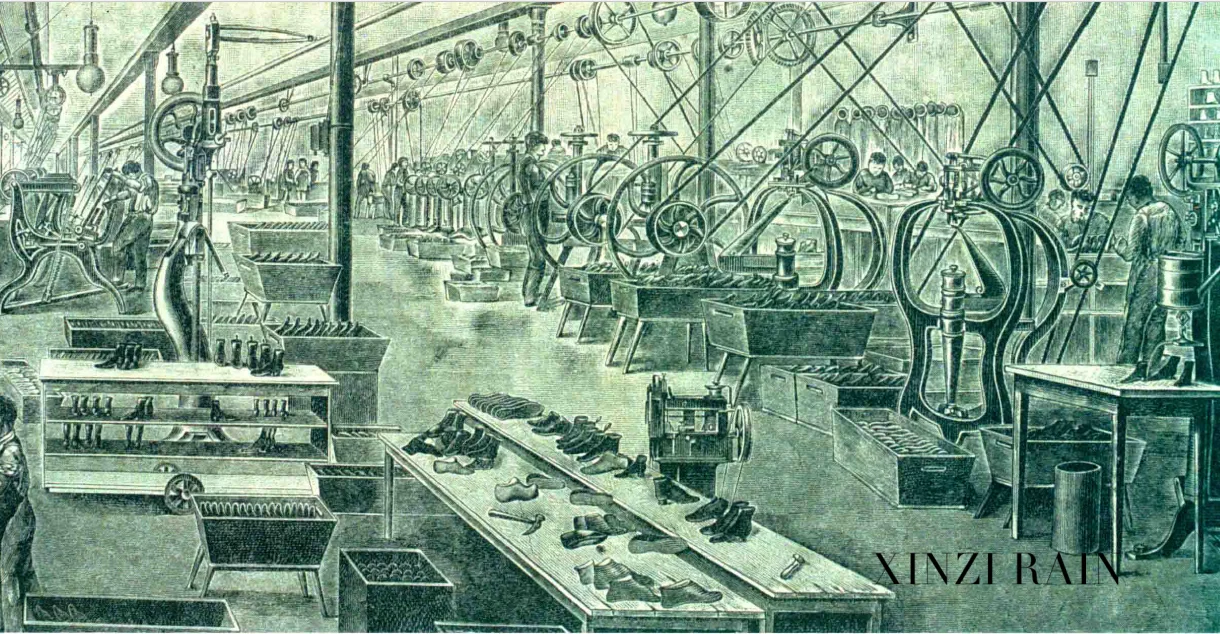

Before industrialization, shoemakers relied solely on physical fasteners — threads, nails, and wooden pegs — to join soles and uppers. The Hand Welt construction emerged in 15th-century Europe, becoming a cornerstone of the continent’s fine shoemaking heritage.

When traditional European craftsmen migrated to North America, they brought these methods with them. As the continent industrialized and the frontier expanded, these techniques evolved into the work boots designed for miners, loggers, and ranchers — giving birth to the American work boot.

By the 19th century, mechanization revolutionized shoemaking. Hundreds of specialized machines — sewing machines, lasting machines, and grinders — transformed handcraft into industrial production. This was the age in which the Goodyear Welt was born.

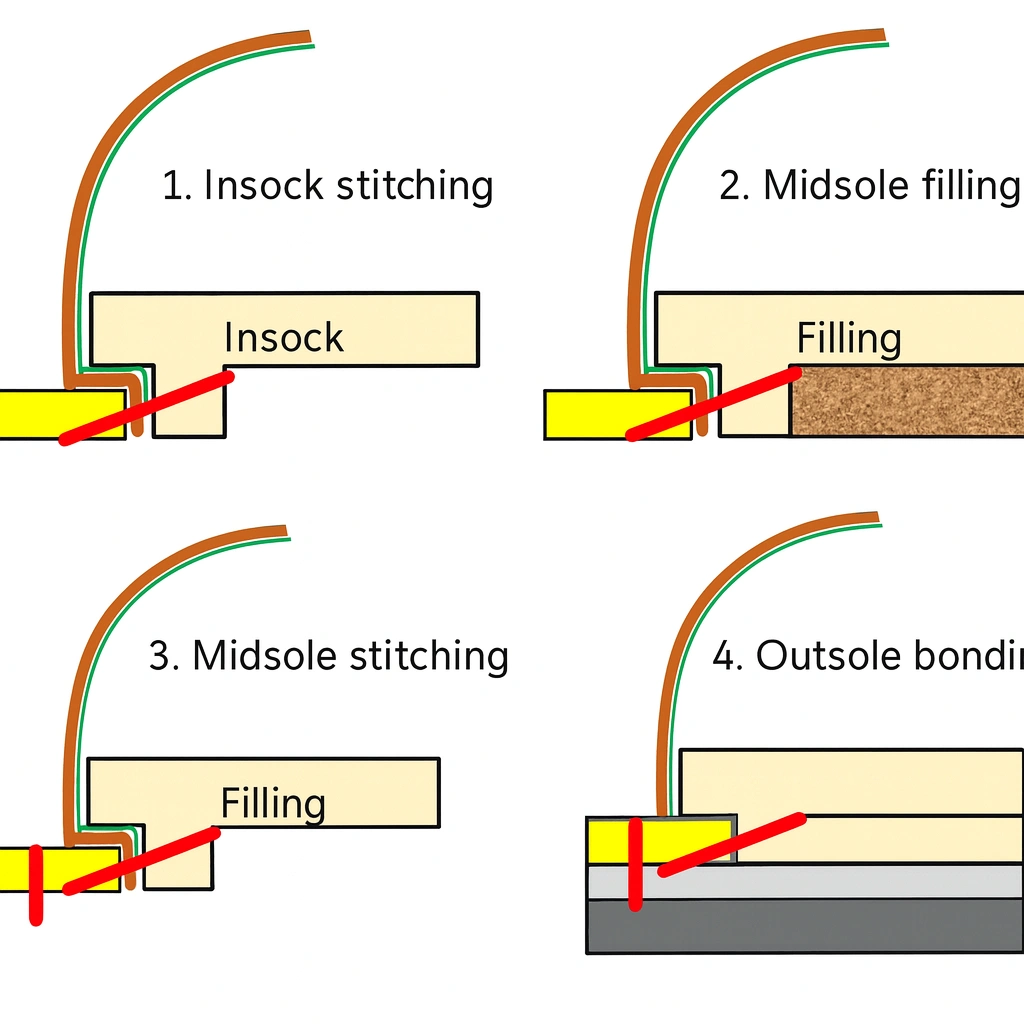

The Hand Welt Process

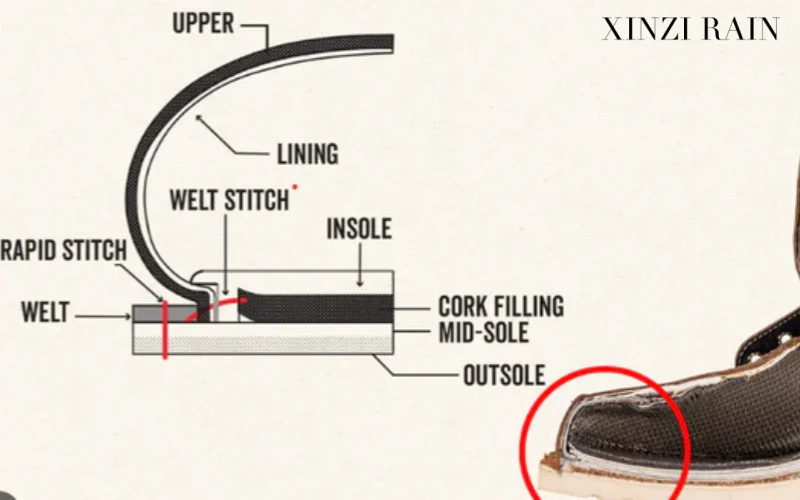

At its core, the Hand Welt construction relies on a welt — a narrow leather strip that bridges the upper and the sole layers. Let’s take the Red Wing 875 as an example (although Red Wing uses a machine process, this model helps illustrate the structure).

Step-by-step process:

A. Preparing the insole.

A channel (groove) is cut into the leather insole to hold the first stitch. The upper, lining, welt, and insole are then hand-sewn together using a curved awl, forming the hidden internal stitch.

B. Filling.

The cavity beneath the insole is filled with cork or another soft, moldable material to provide comfort and flexibility.

C. Attaching the midsole and outsole.

The welt is stitched to the midsole or directly to the outsole, creating the visible external stitch. The outsole can later be replaced without affecting the upper — one of the biggest advantages of this structure.

D. Resoling capability.

Because of its layered structure, a hand-welted boot can be resoled or even rebuilt entirely. Customers can also choose different outsole materials — leather, EVA foam, or rubber — for personalized comfort and performance.

Welt Variations

Not all boots use a full midsole; some stitch the welt directly to the outsole (e.g., Red Wing 8111). Others combine all layers — welt, midsole, and outsole — in a single triple stitch (e.g., Red Wing 9011 Beckman). These variations do not change the essence of the construction.

The Goodyear Welt: Machine-Era Innovation

The Birth of the Goodyear Welt

As industrialization advanced, manual welt stitching gave way to mechanization. In 1871, Charles Goodyear Jr. patented the Goodyear Welt sewing machine, which could replace hand-sewn welts with precise machine stitches — drastically improving efficiency.

(Note: Charles Goodyear Jr. was the son of Charles Goodyear Sr., the inventor of vulcanized rubber. The elder Goodyear had passed away eleven years earlier, so the two should not be confused. The actual inventor behind the Goodyear sewing machine was his employee, August Destouy.)

This machine allowed mass-produced shoes to achieve the strength and durability once limited to hand-crafted footwear — ushering in a new industrial standard.

How the Goodyear Welt Works

Instead of cutting a groove by hand, a canvas rib is glued or stitched to the insole to form the welt seat. The Goodyear sewing machine uses a curved needle to sew through the upper, welt, and canvas rib — effectively replicating the hand-welted inner stitch.

Then, the Rapid Stitch machine (invented by Lyman Reed Blake) is used to attach the welt, midsole, and outsole together with the outer stitch.

This mechanized process dramatically speeds up production while preserving the durability of traditional welted shoes.

Common Misconceptions

Myth #1 — “Handmade Goodyear Welt.”

This is a contradiction in terms. If it’s hand-stitched, it’s Hand Welt, not Goodyear Welt. The latter by definition involves a machine performing the internal stitching.

Myth #2 — “The Goodyear who invented vulcanized rubber also invented this method.”

Incorrect. The vulcanization inventor was Charles Goodyear Sr.; the Goodyear Welt was patented by his son, Charles Goodyear Jr., and actually developed by August Destouy. The Goodyear Tire & Rubber Company was later named in honor of the elder Goodyear but has no relation to Goodyear-welted footwear.

Hand Welt vs Goodyear Welt — Key Differences

-

Efficiency: Machine-stitched Goodyear Welts can be completed in minutes, while hand-welted boots take hours.

-

Durability: Hand-welt stitches form locked stitches; Goodyear machines use chain stitches, which may unravel if broken.

-

Aesthetics: Machine stitching limits how much the waist can be “tightened,” resulting in a broader, more squared profile. Hand-welted and bespoke shoes can achieve the elegant fiddle-back waist by manually concealing stitches in a blind waist — a level of refinement impossible by machine.

Advanced Variations of Goodyear-Type Constructions

Storm Welt (High Edge Welt)

To improve water resistance, a raised welt — called a Storm Welt — is used, covering the seam between the upper and the welt to prevent water ingress. Originally derived from the Norwegian stitch, this technique is ideal for rugged outdoor boots.

¾ Welt and Full Welt

Not all shoes use a full 360° welt. Many boots (such as Red Wing 8111 and 901X) and most dress shoes use ¾ or ½ welts, attaching the heel area with nails or wooden pegs (nail-down construction) instead. This creates a slimmer, more elegant waist.

Dr. Martens’ Heat-Sealed Construction

Dr. Martens uses a unique twist on the welted method. The upper, welt, and insole are still sewn together — but the welt-to-sole connection is achieved by heat-fusion, not stitching. A hot metal blade melts the PVC welt and sole together, forming a permanent seal — a process often referred to as “heat-sealed” or “welded” construction.

The iconic yellow stitching visible around the sole is decorative, inspired by the Norwegian stitch aesthetic.

Final Thoughts

The Goodyear Welt and Hand Welt constructions represent the perfect marriage of craftsmanship and industrial progress. Emerging from centuries of European shoemaking and refined through 19th-century mechanization, these methods embody timeless ingenuity.

Today, the Goodyear Welt is not a marker of luxury alone — it is simply one structural approach. Whether the insole is leather or fiberboard, the welt leather or PVC, the essence remains the same: a layered, rebuildable, durable shoe construction designed to stand the test of time.

True appreciation for classic bootmaking lies not in blind nostalgia, but in understanding its engineering and spirit — respecting tradition while embracing innovation.

Xinzirain: Continuing the Craftsmanship Legacy

At Xinzirain, we share the same respect for craftsmanship that defines heritage brands like Red Wing and White’s Boots. As a professional OEM / ODM footwear manufacturer, our team combines traditional welted techniques with modern design and production efficiency to serve global brands and distributors.

From hand-welted leather boots to injection-molded work shoes, Xinzirain offers custom design, small-batch prototyping, and scalable bulk production — helping our partners bring timeless quality to modern markets.

Our mission is simple:

To turn every fashion idea into a tangible, enduring product — merging craftsmanship with innovation for the world’s next generation of footwear.

More High-End Work Boot Brands Worth Knowing

White Kloud (Japan)

Founded by master shoemaker Shinichi Yamashita, White Kloud represents the pinnacle of Japanese bespoke craftsmanship. Each pair is fully handmade from the last to the stitching, known as “the god-tier of work boots.”

Signature model: Blucher 87

Buco by The Real McCoy’s (Japan / USA)

Originally an American motorcycle gear brand from Detroit, later revived by The Real McCoy’s in Japan. Buco merges the wildness of vintage biker culture with precise Japanese construction.

Signature model: Horse Butt Engineer Boots

Authentic Shoe & Co (Japan)

Created by Tokyo craftsman Shinichi Takehara, this label focuses on minimalist design and flawless handwork. As the premium line of Gallery of Authentic, it embodies quiet luxury in Japanese bootmaking.

Signature model: Classic Engineer Series

(Image from 33OZ forum "polska")

Role Club (USA)

Founded in Los Angeles by Brian the Bootmaker, Role Club is known for custom handmade boots crafted to the wearer’s exact foot measurements. Every pair reflects the maker’s personal touch and timeless dedication.

Signature model: Role Club Engineer Boots

John Lofgren (Japan)

An American designer who rebuilt the soul of vintage Americana through Japanese craftsmanship. Using premium Horween leathers and classic construction, John Lofgren boots blend rugged utility with refined aesthetics.

Signature model: CXL Engineer Boots

Clinch (Tokyo, Japan)

Run by Matsura Minoru of Brass Tokyo, Clinch is loved by collectors for its narrow silhouettes, Latigo leather, and hand-sewn welt construction. The boots are built to last decades while aging beautifully.

Signature model: Lace-up Boots / Engineer Boots

Mister Freedom (Los Angeles, USA)

A brand that celebrates 1950s American workwear culture, blending denim heritage with handcrafted leather boots. Mister Freedom’s rugged style tells the story of vintage America through craftsmanship.

Signature model: Road Champ Boots

Zerrow’s (Japan)

A small workshop established in 2011 by a group of seasoned Japanese craftsmen. Zerrow’s is known for its heavy-duty handmade engineer and motorcycle boots—no mass production, just pure dedication.

Signature model: Engineer Boots

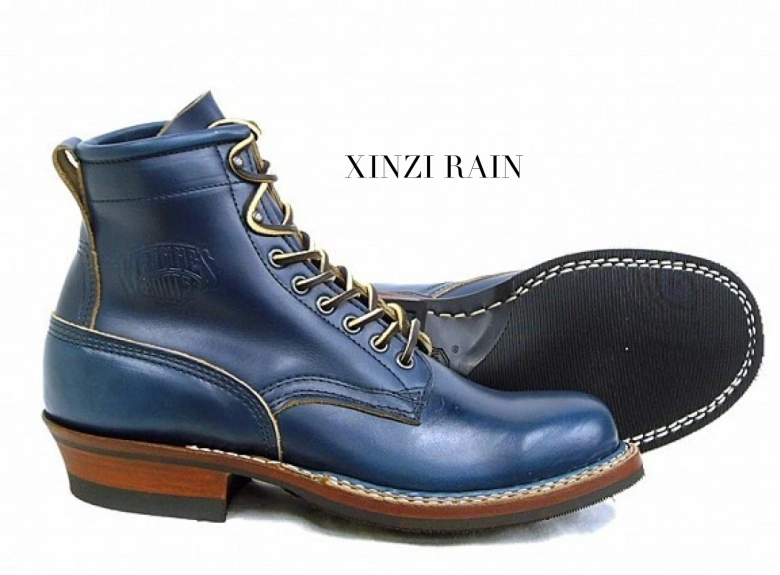

Viberg (Canada)

A family-owned bootmaker since 1931, Viberg is synonymous with luxury work boots. Their 2030 last Service Boots are iconic for combining durability, precision, and understated elegance.

Signature model: 2030 Service Boots

Each of these brands tells a story of craftsmanship, patience, and passion.

They remind us that true quality is not about trends or speed,

but about the hands that shape the leather — and the time it takes to make it right.

In a world driven by automation, these bootmakers keep alive a rare art —

the art of turning work into beauty, and craft into legacy.