If you are preparing to launch a crossbody bag yet face high MOQ requirements, slow sampling, or struggles turning a designer’s vision into manufacturable construction, this article outlines how Xinzirain helps brands overcome these challenges through design collaboration, Italian-level craftsmanship, and flexible manufacturing.

Common Pain Points When Bringing a Crossbody Bag Design to Life

Developing a crossbody bag may seem straightforward, but brands—especially in Europe, the Middle East, Japan, and North America—frequently encounter several recurring obstacles that slow down product launches or compromise the final result.

High MOQ Requirements Limiting New Product Testing

Many factories require 300–500 units per style, which forces designers or small brands to commit significant capital too early. Since crossbody bags often involve multiple layers—outer leather, lining, reinforcement, edge-painting, structured components—the investment becomes even more constraining.

Slow Sampling That Delays Market Windows

A first-sample timeline of 15–25 days is common in traditional workshops. But for fast-moving brands that test designs online or through pre-orders, this pace may cause them to miss critical selling moments.

Craftsmanship Gaps That Change the Original Design

The physical sample often fails to reflect the designer’s concept. Typical issues include:

- uneven edge-painting or inconsistent layers

- stitch density below professional standards (ideal is 8–10 stitches per inch)

- panel deformation caused by incorrect reinforcement

- mis-matched hardware colors and finishes

For a product category where edge quality and silhouette define the perceived value, these discrepancies directly reduce the marketability of the bag.

Concerns About IP Security and Confidentiality

Independent designers and early-stage brands often worry their sketches, hardware molds, and brand identifiers may be reused or shared without consent. This concern is justified in many markets with weak IP governance.

How Xinzirain Solves the Core Challenges in Crossbody Bag Development

Xinzirain is a B2B manufacturer specializing in premium shoes and bags for the European and American markets. With design-engineering support, flexible production, and internationally compliant materials, we minimize the uncertainties brands face when developing a new crossbody bag.

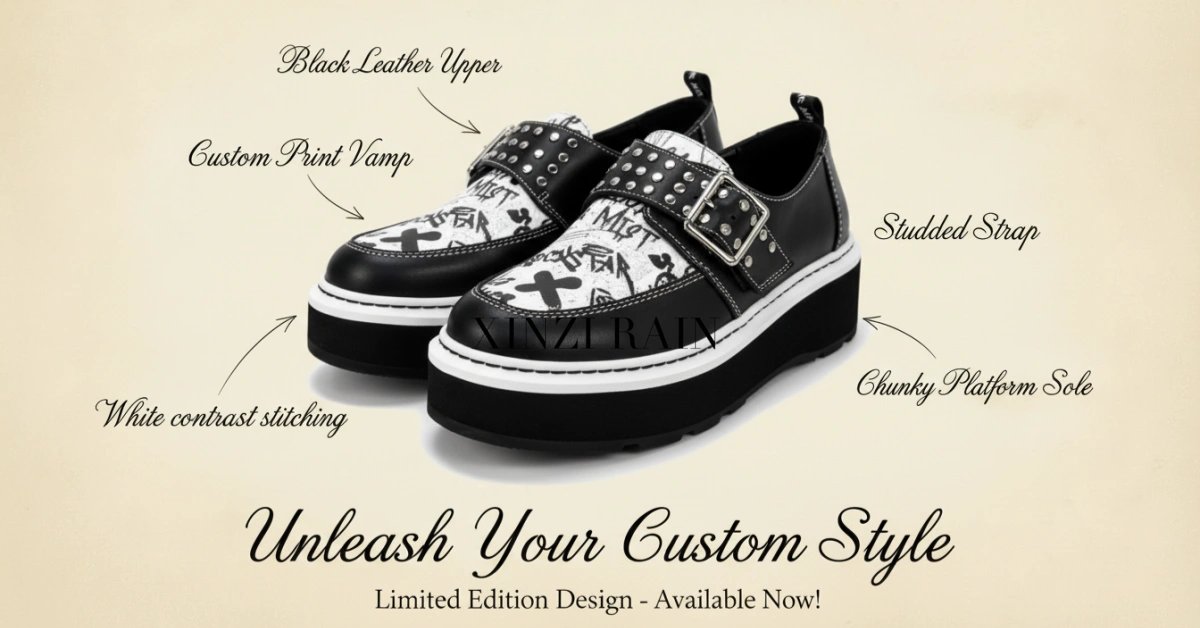

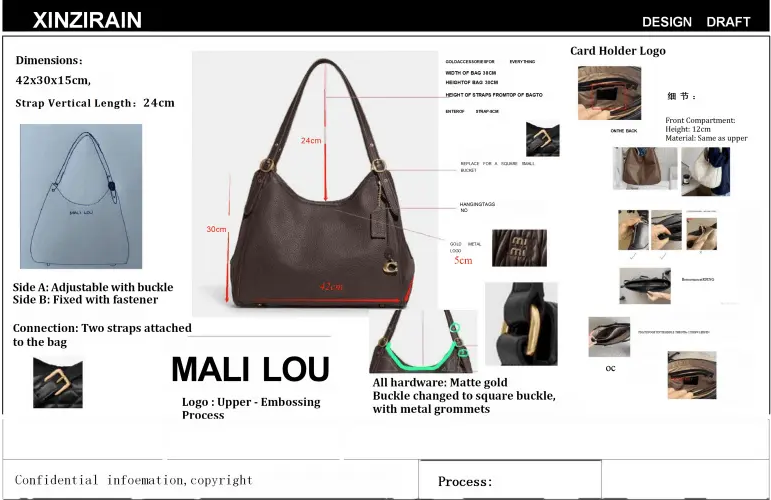

Professional Design and Pattern-Making Support

Our crossbody bags designer team provides:

- feasibility evaluation on structure, leather thickness, and hardware options

- revisions within 24 hours based on designer feedback

- pattern optimization to ensure accuracy in panel alignment, curvature, and overall silhouette

This collaborative approach ensures that what arrives as a sketch can be engineered into a high-end, manufacturable product.

True Low-MOQ Flexibility Starting at 100 Pieces

Xinzirain supports a 100-piece MOQ for leather crossbody bags. This allows emerging brands to:

- test new product categories without overcommitting

- launch limited runs

- validate consumer response before larger orders

Multiple colors, hardware finishes, and leather types can be produced within one batch, enabling highly flexible market testing.

Italian-Level Craftsmanship and Globally Compliant Materials

We follow craftsmanship standards rooted in Italian leatherwork traditions:

- multi-layer edge-painting with sanding between coats

- consistent stitch lines at 8–10 spi

- symmetric panel construction to ensure balance and shape retention

- carefully calibrated reinforcement structures

Leather is sourced from suppliers aligned with the Leather Working Group (LWG). All materials comply with EU REACH and US CPSIA, ensuring that your custom leather crossbody bag meets international regulations without risk.

Efficient Yet Precise Sampling and Production Timelines

Our flexible production system supports:

- sample delivery within 15–27 days

- small-batch production in 25–35 days

- full production runs in 35–45 days

This efficiency allows brands to maintain momentum through design iterations, market testing, and production scaling.

A Realistic Case: Supporting a Scandinavian Minimalist Brand

A Copenhagen-based minimalist accessories label needed a saddle-shaped crossbody bag with hand-finished edges, a custom matte hardware set, and strict silhouette stability. The brand also needed delivery within 60 days for a product-launch collaboration.

Xinzirain provided:

- a structural feasibility study within 48 hours

- first sample in 17 days

- batch production of 80 pieces in 35 days

- leather options from LWG-aligned tanneries

The launch achieved strong sell-through, with a return rate below 1.2%.

Are Crossbody Bags Still Fashionable? What Styles Lead the Global Market?

Are crossbody bags still fashionable?

Yes. According to global insights referenced in McKinsey’s fashion analysis, consumer demand continues to shift toward lightweight, functional, and hands-free accessories. Crossbody bags benefit from this macro-trend and remain consistently relevant across age groups and markets.

What is the most popular crossbody bag?

Across Xinzirain’s international clients, the following silhouettes consistently outperform others:

- structured box-shaped crossbody bag

- curved saddle bag

- compact mini crossbody bag

- soft-construction hobo crossbody bag

- logo-hardware-driven designer crossbody bags

These designs balance practicality, brand identity, and production feasibility—key factors that predict long-term market performance.

Recommended Next Steps for Brands and Designers

If you are considering a new crossbody bag project, the most efficient workflow is:

Submit your sketches for a free feasibility review.

We evaluate structure, material suitability, and cost drivers.

Request the full leather and hardware catalogue.

Options include LWG-aligned leathers, custom molds, and reinforced core materials.

Approve the engineering drawing and proceed to sampling.

Rapid prototyping allows quick refinement.

Produce a low-risk 100-piece batch to test your market.

Once confirmed, scale into full production.

To begin, visit www.herrains.com and send your initial design references.

FAQ

1. What is your MOQ? Can I mix colors or materials?

MOQ for leather crossbody bags is 100 pieces, and mixed colors or mixed leather types are fully supported within one production cycle.

2. What is the sampling cost and timeline?

Sampling usually costs 50–150 USD depending on complexity. Delivery time is 15–27 days, including edge finishing and hardware installation.

3. Do you provide IP protection?

Yes. All sketches, branding elements, and hardware molds are handled under strict confidentiality. Files and materials are stored securely and never reused across clients.

4. Are the materials compliant with international standards?

All leathers, linings, and adhesives comply with EU REACH, US CPSIA, and align with LWG environmental best practices.

5. What communication channels do you support?

We support email, WhatsApp, and video meetings. Technical drawings, construction notes, and 3D previews can also be provided.

Internal Link Suggestions

Learn more about our design collaboration process

Explore the complete guide to custom bag manufacturing