Choosing the right clogs manufacturer is a critical step for brands, retailers, and distributors building a scalable footwear line. Whether you are launching your first capsule collection or expanding an existing range, the manufacturer you work with will directly impact product quality, delivery stability, and long-term growth.

As a shoes and handbags manufacturer in China, XINZIRAIN has worked with brands and wholesalers across Europe and North America, supporting OEM, ODM, and private label clogs production. This guide reflects the real criteria professional buyers should consider when selecting a manufacturing partner.

What Does a Professional Clogs Manufacturer Do?

A professional clogs manufacturer is not simply a production facility. For B2B buyers, a reliable manufacturer should provide:

-

Product feasibility and structure evaluation

-

Material and sole recommendations

-

Sampling and fit testing

-

OEM / ODM bulk production

-

Quality control and reorder consistency

At XINZIRAIN, clog projects are handled as long-term product lines rather than one-off orders, ensuring alignment between samples and mass production.

Custom, OEM, and Private Label Clogs Manufacturing Explained

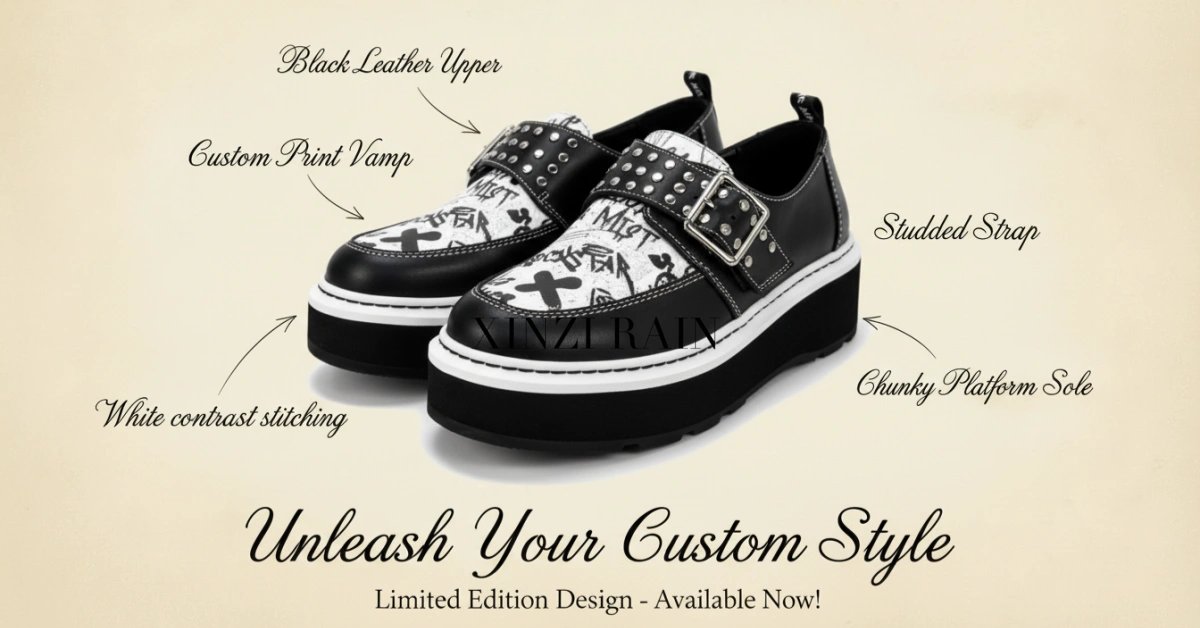

Custom Clogs Manufacturing

Custom clog manufacturing is ideal for brands seeking unique uppers, soles, or branded details. XINZIRAIN supports custom development based on design sketches, reference images, or market concepts.

OEM Clogs Manufacturing

OEM clogs manufacturing follows confirmed designs and specifications, allowing brands to scale production efficiently while maintaining consistent quality.

Private Label Clogs

Private label clogs are suitable for brands testing the market or launching quickly. XINZIRAIN offers flexible private label solutions with controlled customization.

A professional clogs manufacturer should clearly explain which model fits your business stage and budget.

Key Factors to Evaluate When Choosing a Clogs Manufacturer

Experience with Clogs Construction

Clogs require specific expertise in:

-

Wooden and cork sole structures

-

Upper-to-sole fixation

-

Weight balance and stability

-

Comfort for daily, work, or medical use

XINZIRAIN’s manufacturing team has experience producing fashion, casual, and functional clogs for international markets.

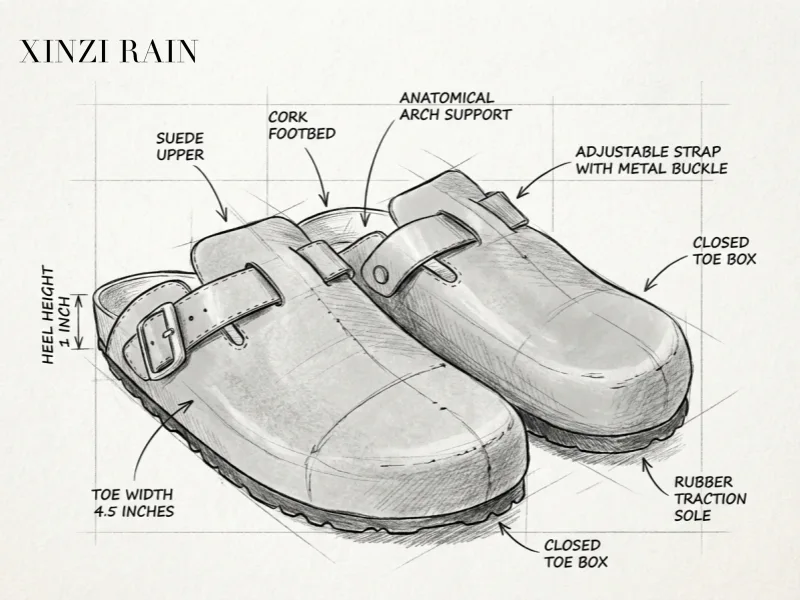

Material Capabilities

A qualified clogs manufacturer should offer:

-

Leather and suede uppers

-

Cork footbeds for comfort

-

Wooden or platform soles

-

Adjustable straps and buckles

Material selection is always aligned with the target market and usage scenario.

MOQ and Production Flexibility

For most projects, MOQ typically starts from 100–300 pairs per style, depending on materials and sole construction. XINZIRAIN works with both emerging brands and established buyers, offering realistic MOQs and scalable production planning.

Export Market Understanding

Manufacturers serving Europe and the US must understand sizing standards, comfort expectations, and quality consistency. This is essential for repeat orders and brand reputation.

Why Many Brands Work with China-Based Clogs Manufacturers

China remains a preferred destination for clog manufacturing due to:

-

Mature footwear and leather supply chains

-

Skilled technicians experienced in clog construction

-

OEM/ODM scalability

-

Strong cost–quality balance

As a China-based manufacturer, XINZIRAIN integrates these advantages with direct factory coordination and clear B2B communication.

Conclusion

Choosing the right clogs manufacturer is not about finding the lowest price—it’s about selecting a manufacturing partner who understands clogs as a product category.

For brands seeking custom clogs, OEM production, or private label solutions, working with an experienced manufacturer like XINZIRAIN helps reduce development risks and supports long-term growth.