Client Profile: A Growing Footwear Brand at a Turning Point

Our client is a mid-sized footwear brand focusing on premium leather shoes for the European market. The brand had already built a loyal customer base through its own online channels and retail partners, but rapid growth exposed limitations in its existing supply chain.

The brand was not simply looking for a factory. They were looking for a leather shoe manufacturer that could act as a long-term production partner—one capable of scaling production while maintaining consistent quality, fit, and delivery reliability.

At this stage, choosing the right leather shoe manufacturer became a critical business decision rather than a sourcing task.

The Challenge: Scaling Without Losing Quality

As demand increased, the brand faced several challenges that many growing footwear companies encounter:

-

Inconsistent quality between production batches

-

Long and unpredictable lead times

-

Limited development support during sample revisions

-

Difficulty scaling volume without compromising craftsmanship

Their previous suppliers could produce leather shoes, but they lacked the systems, communication, and technical depth expected from a professional leather shoe manufacturer serving international brands.

The brand needed a leather shoe manufacturer that could scale responsibly—not one that simply increased output at the expense of quality.

Why the Brand Chose a Professional Leather Shoe Manufacturer

After evaluating multiple suppliers, the brand chose to work with an experienced leather shoe manufacturer specializing in OEM and private label footwear for global markets.

Key reasons behind the decision included:

-

Direct factory communication with no middlemen

-

Strong expertise in leather material selection

-

In-house pattern making and last development

-

Clear production timelines and transparent costing

-

Experience supporting long-term brand growth

Unlike transactional suppliers, this leather shoe manufacturer approached the project with a partnership mindset, focusing on repeat orders and scalable production planning.

The Manufacturer’s Approach: Structured, Transparent, Scalable

Product Review & Manufacturing Assessment

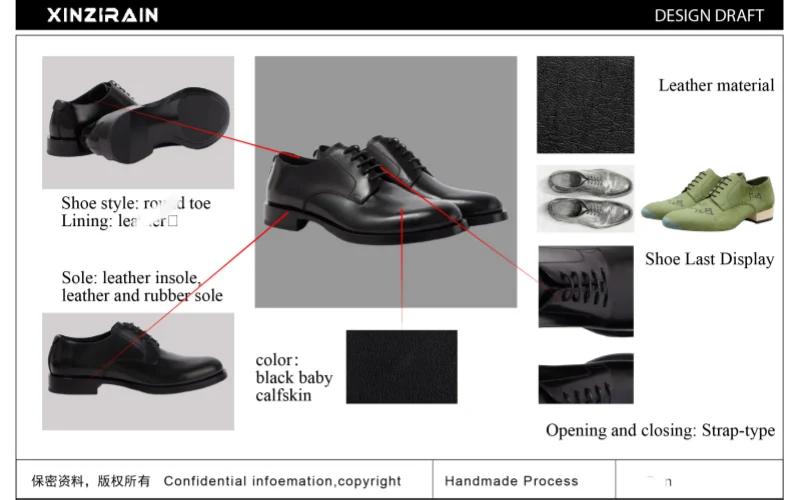

The first step was a full evaluation of the existing product line. The leather shoe manufacturer reviewed:

-

Upper leather thickness and grain consistency

-

Sole structure and durability

-

Stitch density and reinforcement points

-

Fit feedback from previous customer reviews

This allowed the leather shoe manufacturer to identify where minor structural improvements could enhance durability without changing the design language of the brand.

Material Optimization Without Cost Inflation

One of the brand’s main concerns was cost control during scaling. The leather shoe manufacturer proposed alternative leather sourcing strategies, including:

-

Stable full-grain leather suppliers with consistent dye lots

-

Improved lining materials to enhance comfort

-

Optimized outsole compounds for longer wear

By working directly with upstream suppliers, the leather shoe manufacturer achieved better material consistency without increasing unit costs.

Sample Development & Iteration Control

Rather than endless revisions, the leather shoe manufacturer implemented a controlled sample development process:

-

Clear revision checkpoints

-

Written feedback documentation

-

Technical explanations for each adjustment

This structured approach reduced development time and ensured that the final samples were production-ready, not just visually approved.

For the brand, this was a clear difference between a basic factory and a professional leather shoe manufacturer.

Scaling Production: From Small Batches to Stable Volume

Once samples were approved, the focus shifted to scaling.

The leather shoe manufacturer helped the brand move from small trial orders to stable monthly production by:

-

Setting realistic MOQ levels

-

Planning phased production increases

-

Aligning capacity with seasonal demand

-

Implementing batch-level quality inspections

Rather than pushing the brand into risky large orders, the leather shoe manufacturer designed a scalable roadmap that supported sustainable growth.

Quality Control: Consistency Across Every Pair

Quality consistency is where many brands struggle during scaling. The leather shoe manufacturer addressed this through:

-

Standardized production SOPs

-

In-process inspections at key stages

-

Final random sampling before shipment

Each production batch followed the same benchmarks, ensuring that customers received the same quality experience regardless of order size.

This level of control reinforced the value of working with a dedicated leather shoe manufacturer rather than multiple fragmented suppliers.

Results: Measurable Growth With Fewer Risks

Within the first year of cooperation:

-

Production volume increased steadily without delays

-

Product return rates decreased

-

Customer satisfaction scores improved

-

The brand expanded into new retail channels

Most importantly, the brand gained confidence in its supply chain. The leather shoe manufacturer was no longer just a producer, but a strategic manufacturing partner.

Why This Case Matters for Growing Brands

This case highlights a critical truth:

Scaling footwear production is not just about capacity—it’s about choosing the right leather shoe manufacturer.

A professional leather shoe manufacturer offers:

-

Manufacturing insight, not just labor

-

Long-term planning, not short-term output

-

Stability that supports brand growth

For brands looking to scale responsibly, the difference between success and stagnation often comes down to the capabilities of their leather shoe manufacturer.

Looking for a Leather Shoe Manufacturer to Scale Your Brand?

If your brand is preparing to grow—whether you are increasing order volume, launching new styles, or expanding into new markets—working with the right leather shoe manufacturer makes all the difference.

A reliable leather shoe manufacturer doesn’t just make shoes.

They help brands turn growth into a sustainable, repeatable business.

Contact our team to discuss your leather shoe project and scaling goals.

--->Want to learn more about our customer collaboration case studies?