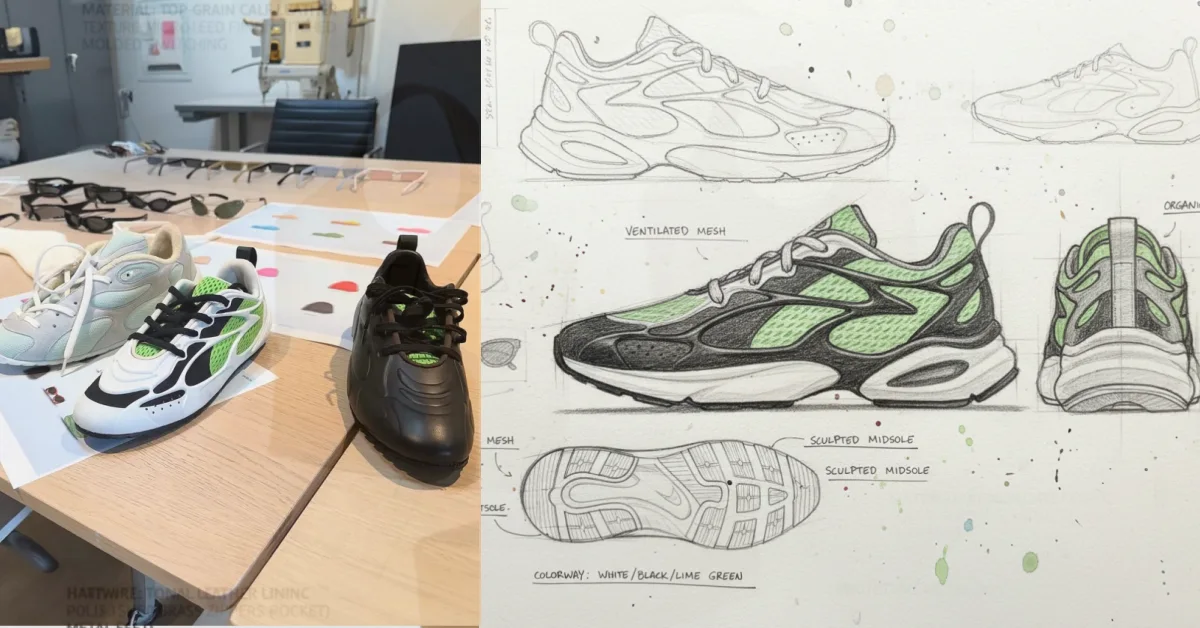

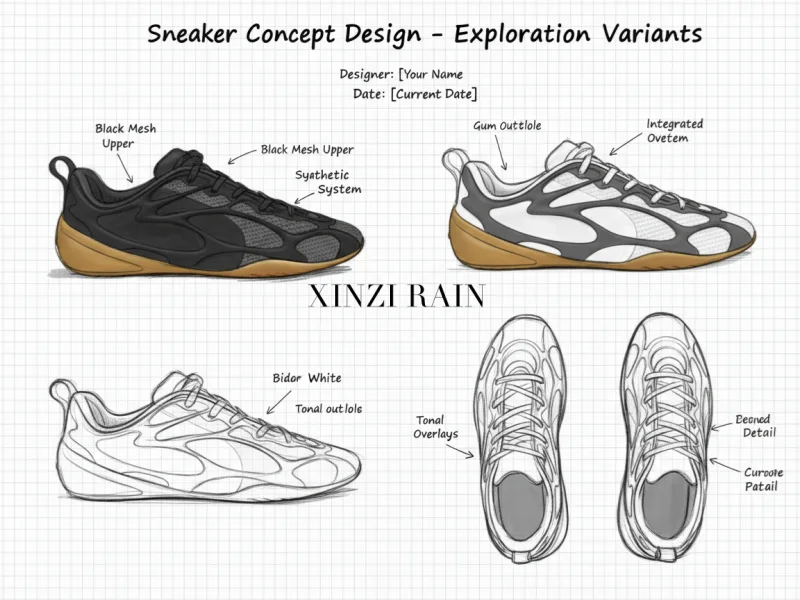

In recent months, a new silhouette has quietly captured the attention of designers, distributors, and sneaker enthusiasts alike. Featuring a sculptural, wave-like upper, modular construction, and a slim 3D-printed sole, this emerging sneaker design has sparked conversation across fashion and footwear circles—especially after being spotted in early wear tests and studio previews.

While social media often frames these moments as hype or celebrity influence, the deeper story is far more meaningful for brands and buyers: this design represents a shift in how modern sneakers are developed, manufactured, and brought to market.

For brands operating in Europe, the United States, and the Middle East, understanding this shift is no longer optional. It is foundational to staying competitive in a rapidly evolving footwear landscape.

A New Design Language: Where Minimalism Meets Technology

The sneaker designs shown in the images reflect several key design directions shaping the global market:

-

A low-profile, thin sole structure, moving away from bulky maximalist midsoles

-

Modular uppers, combining mesh textiles with molded overlays

-

A 3D-printed or digitally engineered sole, designed for precision rather than mass foam pouring

-

Neutral and wearable colorways, supporting everyday styling rather than performance-only use

This design language is not accidental. It reflects growing consumer demand for sneakers that feel lighter, smarter, and more versatile—shoes that move seamlessly between work, travel, and casual environments.

From a manufacturing standpoint, this evolution requires far more than aesthetic updates. It demands new tooling logic, material integration expertise, and closer collaboration between brand and factory.

Why Thin-Sole and 3D-Printed Sneakers Are Gaining Momentum

For years, sneaker innovation focused heavily on cushioning volume. Today, the pendulum is swinging back toward ground feel, flexibility, and ergonomic balance.

Several market forces are driving this change:

-

Urban lifestyles favor lighter, more packable footwear

-

Style-conscious consumers prefer refined silhouettes over exaggerated soles

-

Distributors and retailers seek differentiated products that do not rely solely on logos

-

Sustainability concerns encourage material efficiency and reduced waste

3D-printed sole technology supports these needs by allowing precise structural control. Instead of over-molding foam, manufacturers can engineer sole geometry to deliver support only where needed—reducing weight while maintaining comfort.

For OEM sneaker manufacturers, this represents a move from traditional mass production toward digital-assisted manufacturing, where design and engineering are deeply interconnected.

What This Means for Brands and Distributors

From a B2B perspective, these sneaker designs highlight a critical reality:

Innovation today is as much about manufacturing capability as it is about design creativity.

Brands sourcing sneakers for Europe, North America, or the Middle East must now evaluate factories based on more than price and capacity. Key questions include:

-

Can the factory support custom outsole development, including 3D-printed or hybrid sole structures?

-

Does the manufacturer understand modular upper construction, blending mesh, synthetic overlays, and bonding techniques?

-

Can the factory handle small-batch sampling and iterative prototyping without compromising consistency?

-

Is the production process scalable for future growth, not just initial drops?

This is where many brands struggle. Traditional sneaker factories optimized for standard EVA soles and stitched uppers often lack the flexibility required for next-generation designs.

Materials Matter More Than Ever

The sneakers shown in the images also reflect a careful balance of materials:

-

Engineered mesh uppers for breathability and lightweight wear

-

Synthetic structural overlays to maintain shape and durability

-

Rubber outsoles or hybrid compounds for traction and longevity

-

Digitally engineered midsole components, replacing traditional foam blocks

For a professional sneaker manufacturer, material selection is not just a design choice—it affects tooling costs, MOQ requirements, lead times, and long-term product performance.

Factories capable of advising brands on these trade-offs add significant value, especially for private-label sneaker projects where margins and differentiation matter.

The Manufacturing Challenge Behind the Look

While consumers see a clean, futuristic sneaker, manufacturers see complexity.

Producing this type of footwear requires:

-

Advanced last development to maintain a slim profile without sacrificing comfort

-

Precise bonding and assembly techniques, particularly when stitching is minimized

-

Close coordination between upper pattern engineering and sole geometry

-

Strong quality control, as thin soles and minimalist uppers leave no room for defects

This is why experienced OEM sneaker manufacturers are increasingly involved earlier in the design process, helping brands refine concepts before costly mistakes occur.

Why OEM/ODM Partnerships Are Shifting

The rise of digitally engineered sneakers has accelerated a broader trend:

brands no longer want factories that simply execute—they want manufacturing partners who co-develop.

For distributors and private-label owners, this means choosing factories that offer:

-

Design-to-production integration

-

Material sourcing support

-

Prototyping and testing expertise

-

Flexible MOQs for market testing

-

Scalable production once demand is proven

These capabilities are especially important for brands targeting Europe, the U.S., and the Middle East, where consumer expectations around comfort, finish, and durability are high.

Xinzirain: Supporting the Next Generation of Sneaker Manufacturing

At Xinzirain, we work closely with global brands, distributors, and designers to turn forward-thinking sneaker concepts into market-ready products.

As a professional OEM/ODM sneaker manufacturer, Xinzirain supports:

-

Custom sneaker development, including thin-sole and hybrid constructions

-

Advanced material integration for mesh, synthetic, and sustainable options

-

Small-batch sampling and scalable bulk production

-

One-stop services from design refinement to final delivery

Our experience across footwear categories—combined with a deep understanding of global market expectations—allows us to support brands that want to move beyond imitation and build truly distinctive collections.

Looking Ahead: Sneakers as a Platform, Not a Product

The sneakers shown in these images are not just another trend. They signal a shift toward footwear as a platform for collaboration among design, technology, and manufacturing.

For brands and distributors, the opportunity lies in embracing this shift early—partnering with manufacturers who understand both the creative vision and the technical execution required.

If you are planning to develop custom sneakers, explore innovative sole technologies, or build a private-label footwear line for international markets, Xinzirain is ready to support your journey.

Contact Xinzirain today to discuss your next sneaker project and discover how modern manufacturing can turn ideas into lasting products.